Why Is XLPE a Superior Insulator for Electrical Cables?

Time: 2025-05-26 15:18:23

Source: Henan Province Jianyun Cable Co., Ltd.

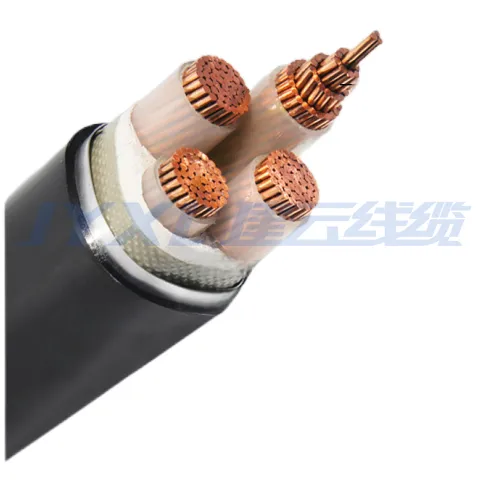

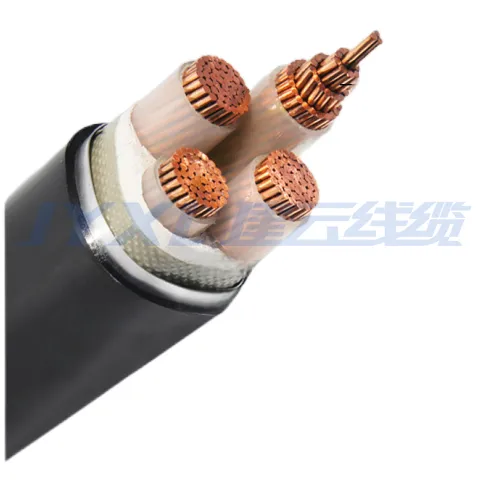

Overview of XLPE Insulation

Cross-linked polyethylene (XLPE) is a widely used insulating material in electrical cables, valued for its exceptional ability to prevent unwanted current flow while withstanding diverse environmental and operational conditions. Unlike standard polyethylene, XLPE undergoes a cross-linking process that enhances its molecular structure, resulting in superior electrical, thermal, and mechanical properties. These characteristics make XLPE a preferred insulator for power cables, as discussed in prior articles on XHHW vs. XLPE, RW90, and TR-XLPE cables.

Chemical Structure and Properties

XLPE’s effectiveness as an insulator stems from its unique chemical structure:

-

Cross-Linking Process: XLPE is produced by chemically or physically linking polyethylene molecules, forming a three-dimensional network. This enhances its stability compared to linear polyethylene.

-

Low Dielectric Constant: XLPE has a low dielectric constant (approximately 2.3), reducing energy loss and improving insulation efficiency.

-

High Dielectric Strength: With a dielectric strength of around 20–30 kV/mm, XLPE can withstand high electric fields without breakdown, ensuring reliable insulation.

-

Non-Polar Nature: Its non-polar molecular structure minimizes electrical conductivity, making it an excellent barrier to current flow.

These properties enable XLPE to provide robust insulation for various voltage levels.

XLPE’s electrical properties make it a standout insulator:

-

Low Power Loss: Its low dielectric loss tangent minimizes energy dissipation, ideal for high-efficiency power transmission, as seen in medium and high voltage cables.

-

High Insulation Resistance: XLPE resists current leakage, ensuring safe operation in cables like RW90 or TR-XLPE.

-

Stability Under Stress: It maintains insulation integrity under high electric fields, suitable for applications requiring consistent performance.

These attributes contribute to XLPE’s reliability in demanding electrical systems.

Thermal Resistance

XLPE’s ability to withstand elevated temperatures enhances its suitability as an insulator:

-

High Operating Temperature: Rated for continuous operation at 90°C, with short-term tolerance up to 250°C, XLPE outperforms many insulators like PVC (typically 70°C).

-

Thermal Stability: The cross-linked structure prevents melting or deformation at high temperatures, ensuring long-term reliability.

-

Cold Resistance: Effective at temperatures as low as -40°C, XLPE remains flexible in cold environments, unlike some rubber insulators.

This thermal resilience makes XLPE ideal for cables in extreme climates, as discussed in RW90 and RWU90 applications.

Environmental Durability

XLPE’s resistance to environmental factors ensures its longevity:

-

Moisture Resistance: Its non-porous structure resists water absorption, making it suitable for wet or underground applications, similar to RWU90 cables.

-

Chemical Resistance: XLPE withstands exposure to oils, acids, and alkalis, ideal for industrial settings, as noted in cable jacket discussions.

-

UV Resistance: When treated or jacketed, XLPE resists degradation from sunlight, enhancing outdoor performance, as explored in RW90 sunlight resistance.

These properties ensure XLPE cables maintain insulation integrity in challenging conditions.

Mechanical Strength

XLPE’s mechanical properties contribute to its effectiveness as an insulator:

-

Tensile Strength: The cross-linked structure provides high tensile strength, resisting stretching or tearing during installation.

-

Abrasion Resistance: XLPE withstands physical wear, ensuring durability in rugged environments, similar to rubber cables like DLO.

-

Flexibility: While less flexible than some rubber insulators, XLPE maintains sufficient flexibility for installation in conduits or trays.

These mechanical attributes enhance XLPE’s practicality in various cable applications.

Advantages of XLPE Insulation

XLPE’s properties translate into several practical advantages:

-

Enhanced Safety: High dielectric strength and insulation resistance minimize electrical faults, ensuring safe operation, as in XHHW or RW90 cables.

-

Longevity: Resistance to thermal and environmental degradation extends cable lifespan, reducing replacement costs.

-

Efficiency: Low dielectric losses improve power transmission efficiency, critical for high voltage cables like TR-XLPE.

-

Versatility: Suitable for low, medium, and high voltage applications, from residential wiring to grid transmission.

-

Cost-Effectiveness: Durable construction reduces maintenance, balancing initial costs, as seen in Jianyun Cable’s XLPE products.

These benefits make XLPE a preferred choice for modern electrical systems.

Applications of XLPE Cables

XLPE’s superior insulating properties support a wide range of applications:

-

Residential Wiring: Low voltage XLPE cables (e.g., RW90, T90) power homes and buildings, offering safety and efficiency.

-

Industrial Distribution: Medium voltage XLPE cables (e.g., TR-XLPE, RWU90) supply power to factories and substations.

-

Power Transmission: High voltage XLPE cables enable long-distance grid connections, ensuring minimal losses.

-

Underground Installations: Moisture-resistant XLPE cables are ideal for direct burial, as in RWU90 applications.

-

Renewable Energy: XLPE-insulated solar cables withstand UV and heat, supporting photovoltaic systems.

These applications highlight XLPE’s adaptability, as discussed in prior voltage classification articles.

Comparison with Other Insulators

The table below compares XLPE with other common cable insulators:

|

Insulator

|

Temperature Range

|

Dielectric Strength

|

Moisture Resistance

|

Applications

|

|

XLPE

|

-40°C to 90°C

|

20–30 kV/mm

|

High

|

Power cables, underground, solar

|

|

PVC

|

-20°C to 70°C

|

10–15 kV/mm

|

Moderate

|

Residential wiring, low voltage

|

|

Rubber

|

-40°C to 90°C

|

15–20 kV/mm

|

Moderate

|

Industrial, flexible cables

|

|

EPR

|

-50°C to 105°C

|

18–25 kV/mm

|

High

|

Medium voltage, industrial

|

Conclusion

Cross-linked polyethylene (XLPE) is a superior insulator for electrical cables due to its exceptional electrical, thermal, environmental, and mechanical properties. Its low dielectric constant, high dielectric strength, and resistance to heat, moisture, and chemicals ensure reliable performance in diverse conditions. XLPE’s cross-linked structure provides thermal stability and mechanical durability, making it suitable for low, medium, and high voltage applications, from residential wiring to power transmission. Compared to insulators like PVC, rubber, or EPR, XLPE offers a balanced combination of efficiency, safety, and longevity, as highlighted in discussions of XHHW vs. XLPE, RW90, and TR-XLPE cables. By selecting XLPE-insulated cables, such as those offered by manufacturers like Jianyun Cable, users can achieve robust and cost-effective electrical systems, ensuring performance and reliability across various projects.