Is RW90 Cable Sunlight Resistant? Properties and Applications

Time: 2025-05-18 15:12:32

Source: Henan Province Jianyun Cable Co., Ltd.

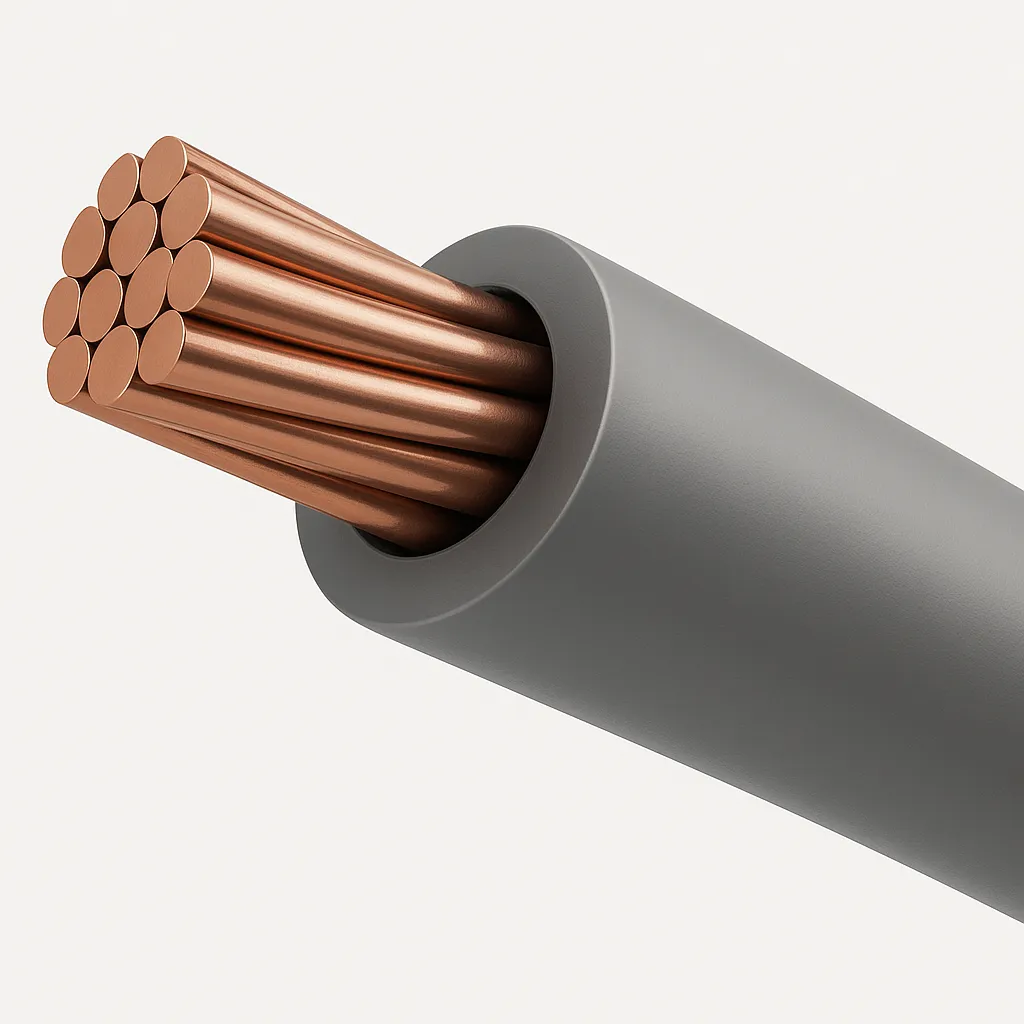

What Is RW90 Cable?

RW90 cable is a single-conductor electrical cable designed for power distribution in dry, damp, or wet environments. It features copper or aluminum conductors insulated with cross-linked polyethylene (XLPE), a thermoset material known for its thermal and mechanical durability. The designation "RW90" indicates a maximum operating temperature of 90°C in dry or damp conditions, making it suitable for resistant wiring applications. RW90 cables are widely used in indoor and outdoor settings, offering a cost-effective alternative to other XLPE-insulated cables like those used in underground or high-heat applications, as discussed in prior articles on insulation materials, moisture-resistant cables, and conduit requirements.

Is RW90 Cable Sunlight Resistant?

RW90 cables exhibit varying degrees of sunlight resistance depending on their construction and installation. Key considerations include:

-

Standard RW90: Most RW90 cables, particularly those without additional jacketing, have limited ultraviolet (UV) resistance. Prolonged exposure to direct sunlight can degrade the XLPE insulation, causing brittleness or cracking, making them unsuitable for unprotected outdoor use.

-

Sunlight-Resistant Variants: Certain RW90 cables are manufactured with UV-resistant XLPE insulation or protective jacketing, enabling them to withstand sunlight exposure. These variants are suitable for outdoor installations, such as in conduits or cable trays, where partial sunlight exposure occurs.

-

Installation Requirements: For outdoor applications, RW90 cables are typically installed in conduits, raceways, or cable trays to shield them from direct sunlight and environmental stress, enhancing longevity. Without such protection, standard RW90 is not recommended for exposed outdoor use, unlike cables with enhanced UV-resistant sheathing.

-

Comparison with Other Cables: Cables with additional UV-resistant sheathing are designed for direct sunlight exposure and are better suited for exposed outdoor or direct burial applications, outperforming standard RW90 in sunlight-exposed environments.

Thus, while some RW90 cables are sunlight-resistant, standard versions require protective measures like conduits to ensure durability in outdoor settings, aligning with practices discussed in articles on conduit-protected installations.

Properties of RW90 Cable

RW90 cables possess properties that support their use in various electrical applications:

-

Temperature Range: Rated for -40°C to 90°C in dry, damp, or wet conditions, ensuring performance across diverse climates.

-

Voltage Rating: Rated for 600V or 1000V, suitable for low-voltage power distribution and branch circuits.

-

Moisture Resistance: XLPE insulation provides good protection against moisture, supporting use in damp or wet locations with conduit protection.

-

Chemical Resistance: Resistant to oils, grease, and chemicals, RW90 withstands moderate industrial environments.

-

UV Resistance: Limited in standard RW90 but enhanced in specific variants with UV-resistant insulation or jacketing, suitable for protected outdoor use.

-

Mechanical Strength: XLPE’s cross-linked structure offers high tensile strength, resisting abrasion during installation.

These properties make RW90 comparable to other high-performance cables, as discussed in prior articles.

Advantages of RW90 Cable

RW90 cables offer several benefits that enhance their utility:

-

Cost-Effectiveness: Aluminum RW90 cables are more affordable than copper equivalents, ideal for large-scale projects, similar to other cost-effective cables.

-

Heat Resistance: Operate reliably at 90°C, surpassing thermoplastic-insulated cables, akin to other XLPE-insulated cables.

-

Moisture Resistance: XLPE insulation ensures performance in damp environments when protected, reducing corrosion risks.

-

Durability: XLPE’s mechanical strength extends lifespan in demanding settings, like other heavy-duty cables.

-

Versatility: Suitable for conduits, cable trays, and raceways, supporting diverse installation methods, similar to multi-core cables.

-

Sunlight-Resistant Options: UV-resistant variants allow protected outdoor use, enhancing flexibility for specific applications.

These advantages make RW90 a practical choice for reliable wiring.

Applications of RW90 Cable

RW90 cables are used across various sectors, similar to applications of conductor sizing, high-performance cables, and photovoltaic cables:

-

Commercial Buildings: Powers lighting, HVAC, and distribution panels in offices, typically in conduits, as discussed in articles on XLPE-insulated cables.

-

Industrial Facilities: Supports motors, control systems, and machinery in factories, leveraging chemical resistance, akin to heavy-duty cables.

-

Outdoor Wiring: Used in conduit-protected setups, such as landscape lighting or signage, with UV-resistant variants for partial sunlight exposure.

-

Underground Installations: Powers detached structures through conduit-housed runs, as opposed to cables designed for direct burial.

-

Renewable Energy: Connects components in photovoltaic systems within conduits, benefiting from UV-resistant options, like photovoltaic cables.

These applications highlight RW90’s role in protected, high-performance installations.

Summary of RW90 Cable Characteristics

The table below summarizes the key characteristics of RW90 cables, highlighting their properties and sunlight resistance:

|

Characteristic

|

Details

|

|

Conductor

|

Copper or aluminum

|

|

Insulation

|

Cross-linked polyethylene (XLPE)

|

|

Temperature Range

|

-40°C to 90°C (dry/damp/wet)

|

|

Voltage Rating

|

600V or 1000V

|

|

Sunlight Resistance

|

Limited in standard versions; enhanced in UV-resistant variants

|

|

Moisture Resistance

|

Good, suitable with conduit protection

|

|

Applications

|

Commercial, industrial, outdoor, renewable energy

|

Tips for Selecting RW90 Cable

Choosing RW90 cables ensures performance and safety in appropriate applications:

-

Assess Sunlight Exposure: Use UV-resistant RW90 variants for outdoor installations with partial sunlight exposure; for direct exposure, prefer cables with enhanced UV-resistant sheathing or install in conduits, as discussed in articles on moisture-resistant cables.

-

Evaluate Installation Environment: Install RW90 in conduits or cable trays for outdoor or damp locations to enhance UV and moisture protection, aligning with conduit installation practices.

-

Select Conductor Material: Choose aluminum for cost savings in long runs, or copper for higher efficiency, as noted in conductor sizing discussions.

-

Determine Load Requirements: Select conductor sizes, such as 2 AWG for 115A with copper, using ampacity guidelines, as discussed in conductor sizing articles.

-

Compare with Alternatives: Opt for RW90 for cost-effective, protected installations; for direct burial or exposed outdoor use, consider cables designed for such conditions, as noted in articles on XLPE-insulated cables.

-

Consult Professionals: Engage electricians to verify cable selection and installation, ensuring reliability, as with household or photovoltaic cables.

These steps align with selecting reliable cables like cross-linked insulation, high-performance, or photovoltaic cables.

Conclusion

RW90 cable, with its XLPE insulation and 90°C temperature rating, is a versatile option for power distribution in dry, damp, or wet environments, but its sunlight resistance varies. Standard RW90 cables have limited UV resistance and require conduit or cable tray protection for outdoor use, while UV-resistant variants can withstand partial sunlight exposure. Compared to cables with enhanced UV-resistant sheathing, RW90 is better suited for protected installations. Its properties, including moisture and chemical resistance, make it ideal for commercial, industrial, and renewable energy applications when properly installed. By selecting appropriate variants, conduit protection, and conductor sizes, users can ensure RW90’s durability and performance, building on discussions of conductor sizing, insulation materials, moisture-resistant cables, and conduit requirements. Professional consultation enhances the reliability of RW90 cable installations, supporting robust electrical systems across various sectors.