How to Choose the Right Electric Wire and Cable for Your Project

Time: 2025-09-08 07:36:42

Source: Henan Province Jianyun Cable Co., Ltd.

Selecting the appropriate electric wire or cable for a project is critical to ensuring safety, performance, and compliance with regulatory standards. Whether for residential wiring, solar photovoltaic (PV) systems, industrial automation, or specialized applications like airport infrastructure or underground mining, the right choice depends on understanding project requirements, environmental conditions, and technical specifications. This guide provides a comprehensive, step-by-step approach to choosing the right wire or cable, with references to high-quality products from Henan Province Jianyun Cable Co., Ltd., presented in a formal and structured manner as of September 2025.

1. Understanding Project Requirements

Choosing the right wire or cable begins with a clear understanding of the project’s electrical, environmental, and regulatory needs:

-

Electrical Load: Determine the current (e.g., 15 A for lighting circuits) and voltage (e.g., 300/500 V for residential, 11 kV for industrial) to ensure the wire or cable can handle the load without overheating.

-

Application Type: Identify whether the project requires fixed wiring (e.g., in-wall residential), flexible connections (e.g., appliances), or specialized cables (e.g., PV or airfield lighting).

-

Environmental Conditions: Assess exposure to UV, moisture, high temperatures (e.g., 40°C in Middle East climates), or mechanical stress (e.g., rockfalls in mining).

-

Regulatory Compliance: Ensure compliance with standards like IEC 60227 (house wiring), IEC 60502-1 (power cables), or FAA AC 150/5345-7F (airfield lighting).

-

Project Scale: Consider the volume (e.g., 10,000 meters for large projects) and installation complexity (e.g., tight bending radii in confined spaces).

2. Key Factors for Selecting Wires and Cables

Several factors influence the choice of wires and cables to ensure safety and performance:

|

Factor

|

Description

|

Considerations

|

|

Conductor Type

|

Material (copper or aluminum) and structure (solid, stranded).

|

Copper offers lower resistance (e.g., <4.61 Ω/km for 4 mm²); aluminum is cost-effective. Stranded (Class 5) for flexibility; solid (Class 1) for fixed wiring.

|

|

Insulation Material

|

Protects against electrical shock and environmental stress.

|

PVC (70°C), XLPE (90°C), or EPR for high temperatures; LSZH for fire safety in confined spaces.

|

|

Voltage Rating

|

Determines suitability for the electrical system.

|

300/500 V for residential, 0.6/1 kV for low-voltage, 11–35 kV for industrial.

|

|

Environmental Resistance

|

Ability to withstand UV, moisture, or chemicals.

|

UV-resistant XLPO for outdoor use; PUR for chemical resistance in mining.

|

|

Mechanical Durability

|

Resistance to abrasion, impact, or bending.

|

Armored cables (SWA) for underground; flexible cables for dynamic applications.

|

|

Fire Safety

|

Flame-retardant and low-smoke properties.

|

IEC 60332-3 for flame-retardant; IEC 60754-1 for LSZH in airports or buildings.

|

3. Types of Wires and Cables for Different Projects

Different projects require specific wire or cable types based on their application:

3.1. Residential Wiring

-

Types: BV (solid copper, Class 1), RV (stranded, Class 5), BVR (semi-flexible, Class 2).

-

Applications: Lighting, power outlets, appliance wiring (300/500 V or 450/750 V).

-

Example: Jianyun Cable’s BV 2.5 mm² for fixed lighting circuits, compliant with IEC 60227.

3.2. Solar Photovoltaic (PV) Systems

-

Types: PV cables with single or twin conductors, UV-resistant.

-

Applications: Connecting solar panels to inverters (4–10 mm², 1.5 kV DC).

-

Example: Jianyun Cable’s TUV-certified PV cables (IEC 62930, EN 50618) with XLPO sheathing.

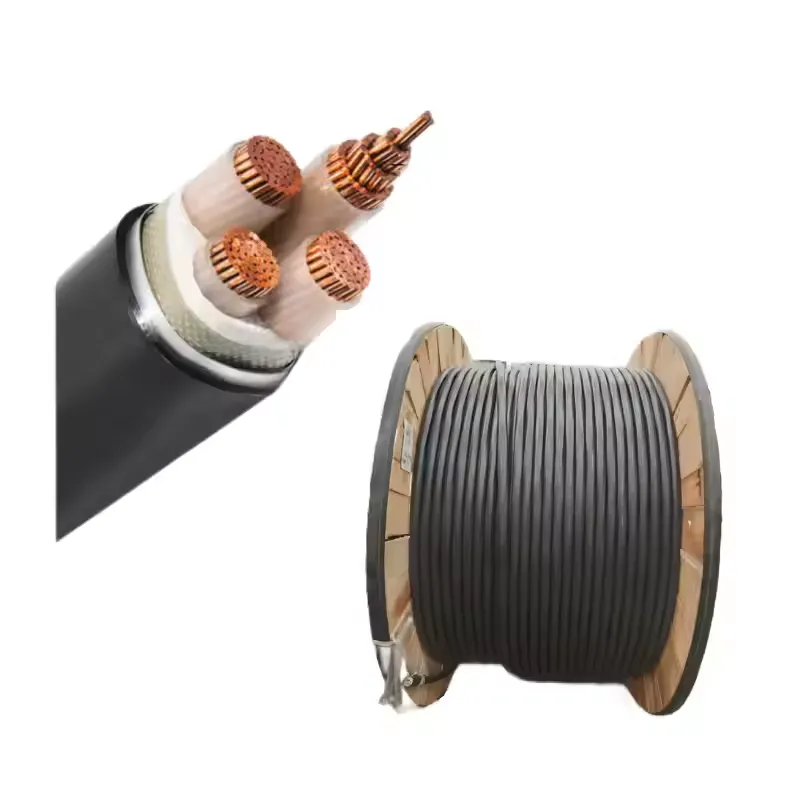

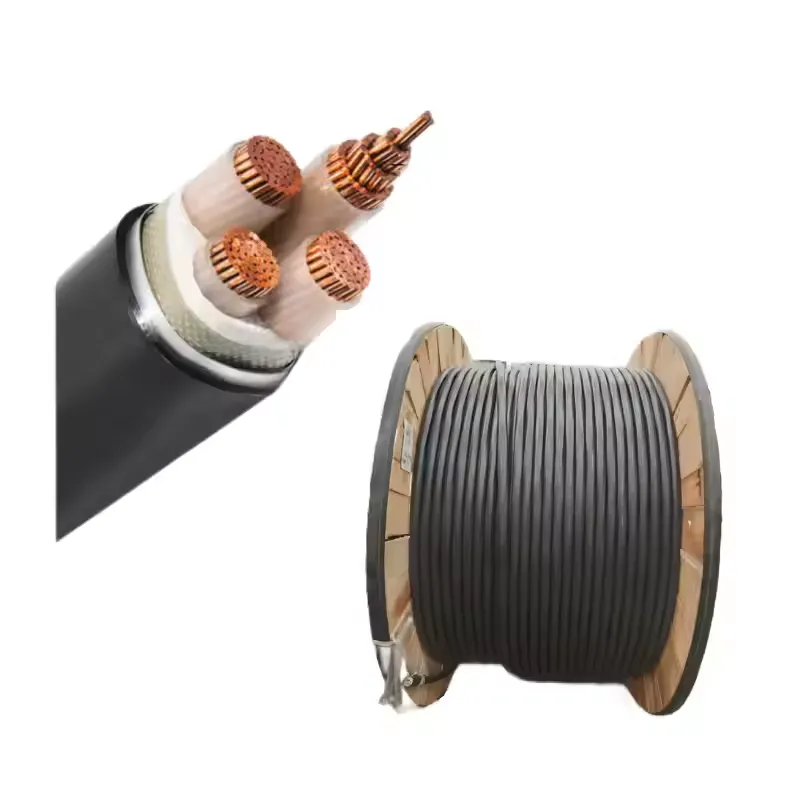

3.3. Industrial and Power Distribution

-

Types: Armored power cables (SWA), medium-voltage cables.

-

Applications: Power supply for factories, airports, or substations (0.6/1 kV to 35 kV).

-

Example: Jianyun Cable’s 11 kV XLPE-insulated, SWA-armored cables (IEC 60502-1).

3.4. Specialized Applications

-

Types: Trailing cables (mining), airfield lighting cables (airports), communication cables.

-

Applications: Mobile equipment, runway lighting, or data networks.

-

Example: Jianyun Cable’s FAA-compliant 5 kV airfield lighting cables and LSZH communication cables.

4. Technical Specifications and Standards

Wires and cables must meet specific technical requirements and standards to ensure safety and reliability:

-

Conductor Specifications:

-

Copper (≥99.9% purity) or aluminum; Class 1 (solid), Class 2 (stranded), or Class 5 (flexible) per IEC 60228.

-

Resistance: <4.61 Ω/km for 4 mm² copper to minimize voltage drop (<1.5%).

-

Insulation and Sheathing:

-

PVC (70°C), XLPE (90°C), or EPR for high temperatures; LSZH for low smoke and toxicity.

-

Dielectric strength: ≥20 kV/mm for insulation integrity.

-

Voltage Ratings:

-

300/500 V or 450/750 V for residential; 0.6/1 kV to 35 kV for industrial; 5 kV for airfield lighting.

-

Standards:

-

IEC 60227: PVC-insulated wires for house wiring.

-

IEC 60502-1: Low-voltage power cables.

-

EN 50618/IEC 62930: PV cables for solar applications.

-

IEC 60332-3: Flame-retardant properties for bundled cables.

-

FAA AC 150/5345-7F: Airfield lighting cables.

-

RoHS/REACH: Restrictions on hazardous substances for EU-influenced markets.

-

Certifications: Jianyun Cable provides TUV, CCC, and ISO 9001-certified products, ensuring compliance with global standards.

|

Specification

|

Details

|

|

Conductor

|

Copper/aluminum, Class 1/2/5 (IEC 60228)

|

|

Insulation

|

PVC, XLPE, EPR, LSZH; ≥20 kV/mm dielectric strength

|

|

Voltage Rating

|

300/500 V to 35 kV

|

|

Standards

|

IEC 60227, IEC 60502-1, EN 50618, FAA AC 150/5345-7F

|

|

Certifications

|

TUV, CCC, ISO 9001

|

5. Steps to Choose the Right Wire or Cable

Follow these steps to select the appropriate wire or cable for your project:

-

Determine Electrical Requirements:

-

Calculate current load (e.g., 15 A for lighting) and voltage (e.g., 230 V single-phase).

-

Use sizing charts (e.g., IEC 60364) to select conductor size (e.g., 4 mm² for 15 A over 50 m, <1.5% voltage drop).

-

Assess Environmental Conditions:

-

Choose UV-resistant XLPO or PUR for outdoor or harsh environments (e.g., Middle East climates).

-

Select LSZH cables for confined spaces (e.g., airports, buildings) to ensure fire safety.

-

Identify Application Type:

-

Use BV wires for fixed residential wiring, RV for flexible appliance connections, or armored cables for industrial power distribution.

-

Select specialized cables (e.g., PV cables, airfield lighting cables) for specific projects.

-

Verify Standards and Certifications:

-

Ensure compliance with relevant standards (e.g., IEC 60502-1, EN 50618) and certifications (e.g., TUV, UL).

-

Request batch-specific test reports (e.g., insulation resistance >1000 MΩ/km) from suppliers like Jianyun Cable.

-

Evaluate Installation Needs:

-

Choose flexible conductors (Class 5) for tight spaces; maintain bending radii (4–6D for cables, 6–8D for wires).

-

Use armored cables for underground or high-impact areas.

-

Partner with a Reliable Supplier:

-

Select manufacturers like Jianyun Cable, offering TUV-certified wires and cables with proven performance (e.g., showcased at Elektro 2025 in Moscow).

-

Request samples, factory audits (e.g., SGS), and transparent pricing with HS codes (e.g., 8544 for insulated cables).

6. Challenges and Solutions

|

Challenge

|

Solution

|

|

Incorrect Sizing

|

Use IEC 60364 sizing charts to match conductor size to load and distance (e.g., 4 mm² for 15 A over 50 m).

|

|

Environmental Damage

|

Select XLPE or PUR cables for UV, moisture, or chemical resistance; use conduits for added protection.

|

|

Counterfeit Products

|

Source from Jianyun Cable with TUV/CCC certifications; verify via official databases (e.g., TUV Certipedia).

|

|

Overheating

|

Apply derating factors (e.g., 0.91 at 40°C per IEC 60364) and ensure proper connections (e.g., 2.5 Nm torque for MC4).

|

|

Regulatory Non-Compliance

|

Confirm compliance with IEC, FAA, or regional standards (e.g., G-Mark for GCC markets).

|

7. Conclusion

Choosing the right electric wire or cable requires careful consideration of electrical load, environmental conditions, application type, and regulatory standards. Wires like BV and RV suit residential wiring, while cables like PV, armored power, or airfield lighting cables are ideal for specialized projects. Compliance with standards like IEC 60227, IEC 60502-1, and EN 50618 ensures safety and performance. Henan Province Jianyun Cable Co., Ltd. offers TUV- and CCC-certified wires and cables, tailored for diverse applications with robust quality control and global reliability. By following a structured selection process and partnering with trusted suppliers, buyers can ensure safe, efficient, and durable electrical systems for 20–30 years.