Time: 2025-04-21 13:29:23 Source: Henan Province Jianyun Cable Co., Ltd.

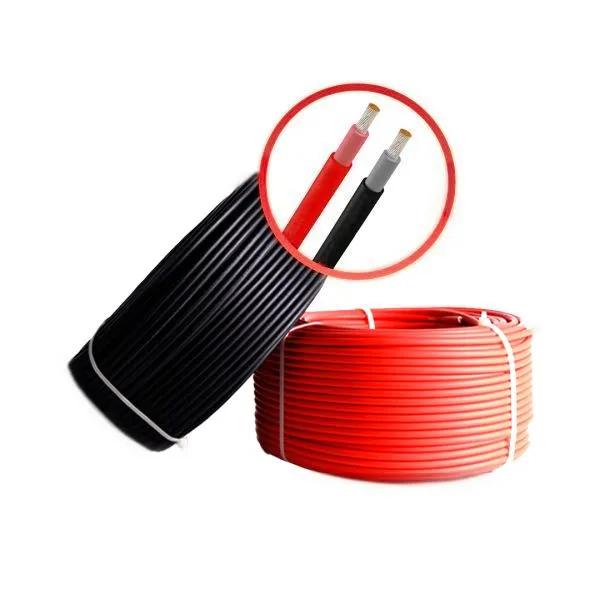

PV Wire: Also known as photovoltaic wire, PV wire is a single-core, insulated cable designed specifically for solar power systems. It connects solar panels to inverters or batteries, handling high DC voltages (up to 2 kV per UL 4703) and currents (e.g., 30–50A for 4–6 mm²). PV wire is engineered to withstand harsh outdoor conditions like UV exposure, extreme temperatures, and moisture, often for 25+ years.

Regular Wire: This term broadly refers to general-purpose electrical wires used in various applications, such as household wiring (e.g., NM-B), control wiring (e.g., SY cable), or power distribution (e.g., THHN). Regular wires are typically designed for AC systems (e.g., 120/240V in homes) or low-voltage control circuits, with insulation suited for indoor or less demanding environments.

PV wire is like a specialized marathon runner, trained to endure the long, harsh race of solar energy systems, while regular wire is a versatile sprinter, tackling shorter, varied tasks in everyday electrical setups.

PV wire and regular wire differ in their design, materials, environmental resistance, and electrical specifications, reflecting their distinct roles. Below is a detailed comparison:

| Feature | PV Wire | Regular Wire (e.g., NM-B, THHN) |

|---|---|---|

| Purpose | Solar PV systems (DC power) | General electrical (mostly AC power) |

| Voltage Rating | Up to 2 kV DC (UL 4703), 1.5 kV (EN 50618) | Typically 600V AC or less (e.g., 120/240V) |

| Insulation | XLPE, double-insulated | PVC or XLPE, single-insulated |

| Conductor | Tinned copper, stranded | Copper/aluminum, solid or stranded |

| Environmental Resistance | UV, weather, -40°C to +90°C | Limited (indoor/dry, -5°C to +70°C typical) |

| Sheath | Halogen-free, flame-retardant | PVC, not always halogen-free |

| Standards | UL 4703, EN 50618, TÜV 2 PfG | NEC, UL 83 (THHN), or local codes |

PV wire uses tinned copper to resist corrosion and XLPE insulation for UV and thermal resistance (up to 90°C wet, 150°C short-circuit), often double-insulated for added safety in high-voltage DC systems. Regular wires like NM-B use PVC insulation, suited for indoor AC applications at 600V or less, but lack the UV resistance needed for outdoor solar setups. PV wire’s halogen-free sheath minimizes toxic emissions, meeting strict solar standards, while regular wire may not prioritize this. It’s like comparing a heavy-duty raincoat (PV wire) for stormy weather to a light jacket (regular wire) for indoor use—one’s built for extreme conditions, the other for everyday comfort.

PV wire and regular wire are applied in different contexts, reflecting their design strengths and environmental tolerances.

Using regular wire in solar systems can lead to insulation breakdown from UV or heat, causing failures or safety risks, while PV wire isn’t cost-effective for simple indoor AC wiring. PV wire is like a rugged outdoor extension cord for solar power, while regular wire is the standard indoor cord for everyday appliances—each excels in its own domain.

PV wire and regular wire differ fundamentally in their design and purpose: PV wire is built for solar systems, with tinned copper, XLPE insulation, and halogen-free sheaths to handle high DC voltages (up to 2 kV) and harsh outdoor conditions (-40°C to +90°C). Regular wire, like NM-B or THHN, is designed for general AC applications (typically 600V or less), using PVC insulation for indoor or protected settings. PV wire is used in solar installations, while regular wire powers homes, buildings, and machinery. Choosing the right wire ensures safety, efficiency, and longevity in electrical systems.