Multi-Conductor vs. Multi-Pair Cables: A Comprehensive Comparison

Time: 2025-05-11 14:27:31

Source: Henan Province Jianyun Cable Co., Ltd.

What Are Multi-Conductor and Multi-Pair Cables?

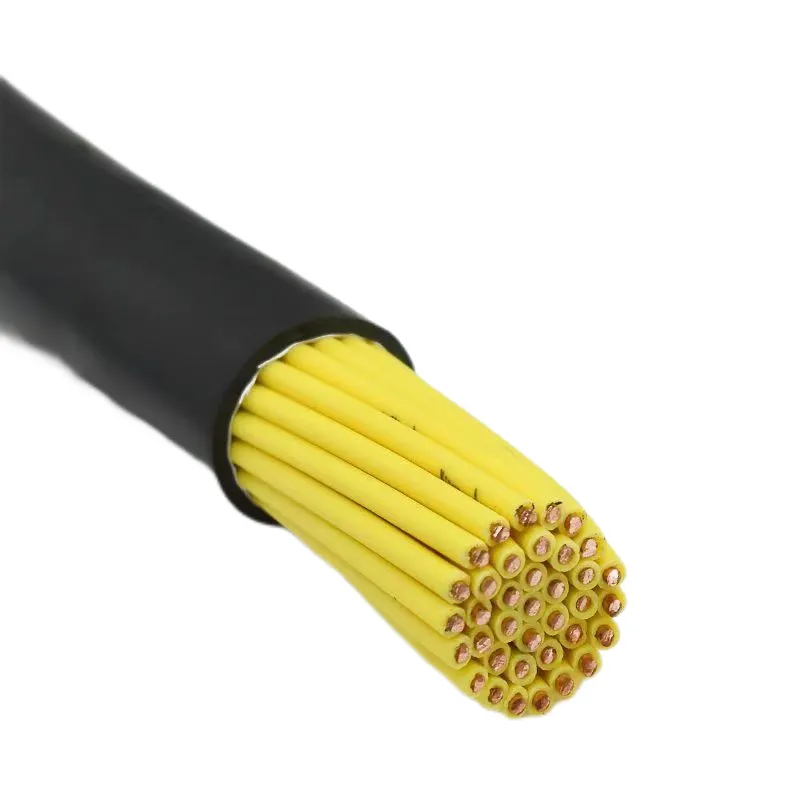

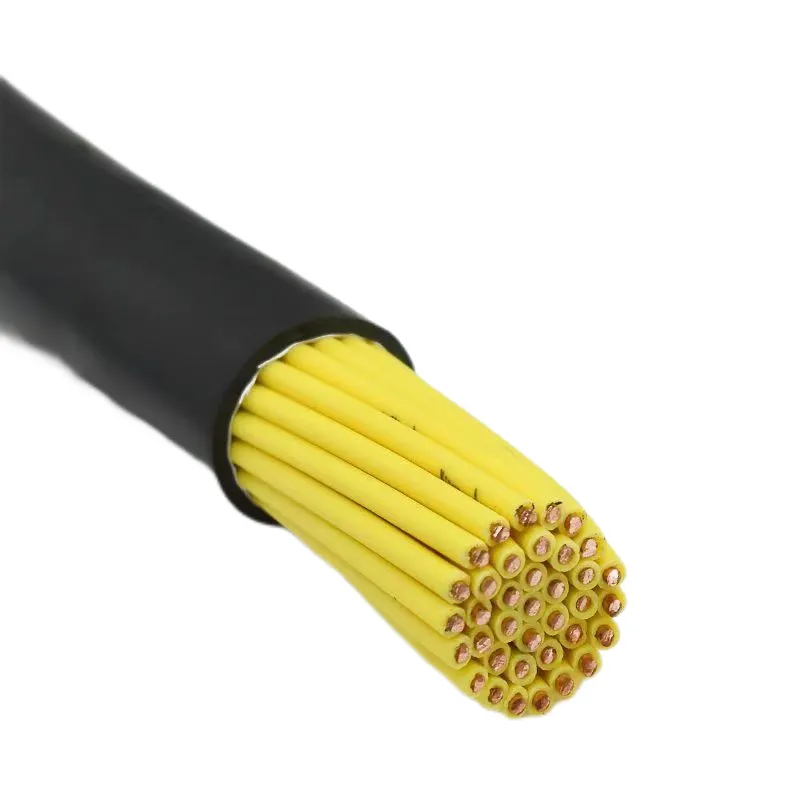

Multi-conductor and multi-pair cables are specialized electrical cables designed to transmit multiple signals or power lines within a single outer jacket. Multi-conductor cables consist of multiple individually insulated conductors, each capable of carrying independent signals or power, making them versatile for power distribution and control systems. Multi-pair cables, often called twisted-pair cables, organize conductors into twisted pairs (typically two or three conductors per pair) to reduce electromagnetic interference (EMI), excelling in data and communication applications. Both cable types are critical in industries like telecommunications, industrial automation, and audio systems, but their structural differences determine their suitability for specific tasks, similar to distinctions between Teflon, PUR, or LSOH cables discussed previously.

Construction Differences

The primary difference between multi-conductor and multi-pair cables lies in their construction:

-

Multi-Conductor Cables:

-

Conductors: Multiple individual conductors (e.g., 2 to 60 cores), each insulated with materials like PVC, polyethylene (PE), or PTFE for electrical isolation.

-

Structure: Conductors are laid concentrically or bundled within a single outer jacket, often with color-coded insulation for identification.

-

Shielding: Optional foil, braid, or spiral shields reduce EMI, though unshielded versions are common for power applications.

-

Conductors: Typically stranded tinned copper (e.g., 14-24 AWG) for flexibility or solid copper for rigidity, depending on the application.

-

Multi-Pair Cables:

-

Conductors: Conductors are grouped into twisted pairs (e.g., 1 to 16 pairs), with each pair insulated and twisted to minimize crosstalk and EMI.

-

Structure: Pairs are cabled together within an outer jacket, often with individual or overall shielding (e.g., foil or braid) for enhanced EMI protection.

-

Shielding: Common configurations include unshielded twisted pair (UTP), shielded twisted pair (STP), or individually shielded pairs for high-performance data transmission.

-

Conductors: Usually stranded copper (e.g., 22-24 AWG) for flexibility, with tighter twisting (smaller pitch) for better interference resistance.

Multi-conductor cables prioritize versatility for multiple circuits, while multi-pair cables focus on signal integrity through twisted-pair design, akin to the specialized roles of PUR or Teflon cables.

The electrical performance of these cables varies due to their design:

-

Multi-Conductor Cables: Suitable for carrying multiple independent signals or power lines (e.g., 20-30 amps for 12 AWG). Without shielding, they are more susceptible to EMI, making them less ideal for high-frequency data transmission. Shielded versions (e.g., with foil or braid) improve performance in noisy environments but are less effective than twisted pairs.

-

Multi-Pair Cables: The twisted-pair design reduces crosstalk and EMI by canceling out noise, making them ideal for low-voltage, high-speed data applications (e.g., Ethernet, RS-232). Shielded multi-pair cables (STP) offer superior noise rejection, with individually shielded pairs eliminating crosstalk in sensitive applications like telecommunications.

Multi-pair cables outperform multi-conductor cables in data integrity, while multi-conductor cables handle higher currents, similar to single-core cables discussed earlier.

Core Configurations and Flexibility

Both cable types support various core counts, impacting their flexibility and use:

-

Multi-Conductor Cables:

-

Core Counts: Available in 2-core (e.g., for single-phase AC), 3-core (e.g., for three-phase motors), 4-core (e.g., for low-voltage distribution with neutral), or up to 61 cores for complex control systems.

-

Flexibility: Stranded conductors enhance flexibility for dynamic applications, while solid conductors are stiffer for fixed installations.

-

Multi-Pair Cables:

-

Pair Counts: Common configurations include 1-pair, 4-pair (e.g., Cat5e Ethernet), or up to 16 pairs for advanced communication systems.

-

Flexibility: Tighter twisting and stranded conductors make multi-pair cables more flexible, ideal for applications requiring bending, like computer peripherals.

Multi-conductor cables are versatile for power and control, while multi-pair cables are optimized for compact, flexible data transmission, contrasting with the rigidity of MV cables or the heat resistance of Teflon cables.

Applications of Multi-Conductor and Multi-Pair Cables

Each cable type serves distinct applications based on its design:

-

Multi-Conductor Cable Applications:

-

Power Distribution: Used in residential (e.g., 2-core for single-phase appliances) and industrial settings (e.g., 3-core for three-phase motors).

-

Industrial Control Systems: Supports automation and machinery with 4-core or higher cables for multiple control circuits.

-

Audio Systems: Powers multi-channel audio equipment, requiring multiple conductors for simultaneous signal transmission.

-

Building Wiring: Employed in low-voltage distribution systems, similar to THHN or TFFN cables, for lighting and HVAC.

-

Multi-Pair Cable Applications:

-

Telecommunications: Used in telephone, fiber optic, and Ethernet systems (e.g., Cat5e, Cat6) for high-speed data with minimal crosstalk.

-

Computer Networks: Supports LANs and data transmission with UTP or STP cables, reducing EMI in office environments.

-

Audio/Visual Systems: Employed in recording and broadcasting for low-noise signal transmission, often with shielded pairs.

-

Automation Controls: Connects sensors and controllers in robotics, ensuring reliable data transfer in high-EMI settings.

Multi-conductor cables are akin to PUR cables for robust power applications, while multi-pair cables resemble LSOH cables for low-smoke, high-integrity data needs.

Multi-Conductor vs. Multi-Pair Comparison Table

The table below summarizes the key differences between multi-conductor and multi-pair cables:

|

Feature

|

Multi-Conductor Cable

|

Multi-Pair Cable

|

|

Construction

|

Multiple individual conductors

|

Conductors twisted into pairs

|

|

EMI Resistance

|

Moderate (requires shielding)

|

High (twisted pairs reduce crosstalk)

|

|

Flexibility

|

Moderate (depends on stranding)

|

High (tighter twists, stranded conductors)

|

|

Applications

|

Power distribution, control systems

|

Data transmission, telecommunications

|

|

Shielding

|

Optional (foil, braid)

|

Common (UTP, STP, individual shields)

|

|

Core/Pair Count

|

2 to 61 cores

|

1 to 16 pairs

|

|

Typical AWG

|

14-24 AWG

|

22-24 AWG

|

Note: Verify specifications with NEC or a professional electrician for specific applications.

Tips for Choosing Between Multi-Conductor and Multi-Pair Cables

Selecting the right cable requires careful consideration of application needs:

-

Assess Signal Type: Choose multi-conductor cables for power distribution or control signals (e.g., 4-core for low-voltage systems) and multi-pair cables for data or communication (e.g., 4-pair Cat5e for Ethernet).

-

Evaluate EMI Environment: Use shielded multi-pair cables (STP) in high-EMI settings like factories; opt for shielded multi-conductor cables for moderate noise environments.

-

Match Gauge to Load: Select AWG sizes (e.g., 12 AWG for 20-30 amps in multi-conductor) to prevent overheating, adhering to NEC guidelines.

-

Consider Flexibility: Choose stranded conductors in multi-pair cables for dynamic applications; use solid conductors in multi-conductor cables for fixed setups.

-

Verify Certifications: Ensure UL, RoHS, or CSA compliance, especially for multi-pair cables in telecommunications or multi-conductor cables in industrial settings.

-

Plan for Space and Installation: Multi-pair cables are compact for data applications, while multi-conductor cables simplify power distribution but may require more space.

-

Consult Professionals: Work with licensed electricians for complex installations, such as multi-core control systems or high-speed network cabling, to ensure compliance.

These tips help optimize cable selection for performance and safety.

Conclusion

Multi-conductor and multi-pair cables serve critical roles in electrical and communication systems, but their differences in construction and performance dictate their applications. Multi-conductor cables, with multiple individual conductors, excel in power distribution and control systems, supporting high currents and versatile core counts (e.g., 4-core for low-voltage distribution). Multi-pair cables, with twisted pairs, are optimized for data transmission and telecommunications, minimizing EMI and crosstalk for reliable signal integrity. Available in configurations like 2-core to 61-core or 1-pair to 16-pair, both types require careful selection based on electrical load, environmental conditions, and industry standards. By understanding their properties and consulting professionals, you can choose the right cable for efficient, safe performance in applications ranging from industrial automation to high-speed networks.