Time: 2025-06-09 07:32:46 Source: Henan Province Jianyun Cable Co., Ltd.

Identify the conditions the cable will face—such as exposure to oil, chemicals, UV, extreme temperatures, abrasion, or continuous motion. Continuous-flex cables are essential for applications like robotics, conveyors, and moving machinery.

Choose based on environmental demands:

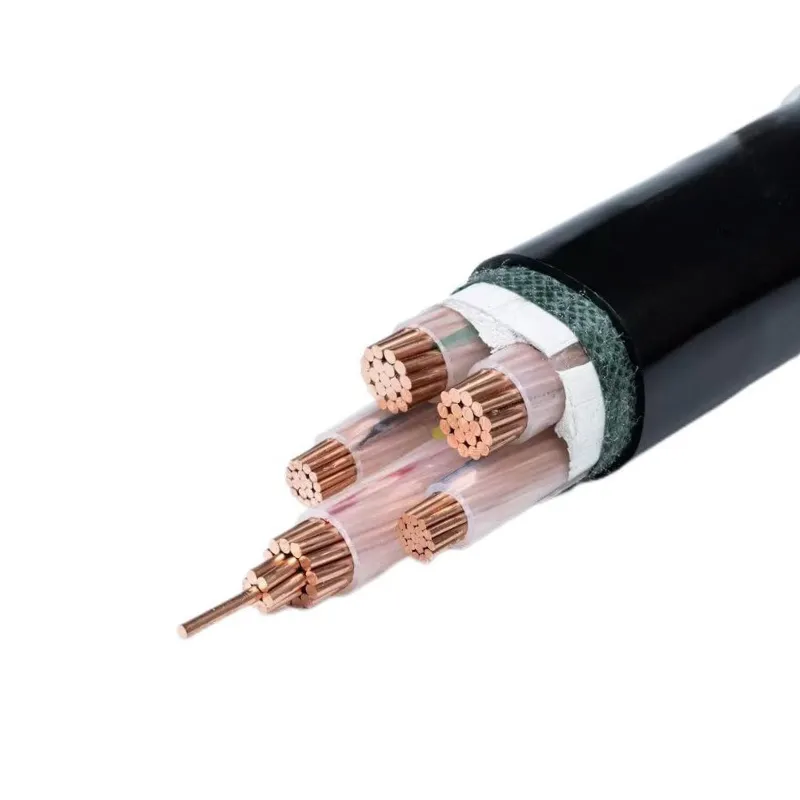

For frequent bending or flexing, select cables with high-strand-count stranded conductors (IEC Class 5 or 6) to resist fatigue better than solid cores.

Use braided or combined foil+braid shields to balance EMI protection and flexibility—ideal for industrial signal and data applications.

Check for relevant certifications such as UL, IEC, NEC, RoHS/REACH, and fire-resistance ratings (e.g., UL 444) to ensure safety, compatibility, and legal compliance.

| Aspect | Recommendation |

|---|---|

| Environment | Oil/UV/motion → PUR or TPE; high-temp/fire → Silicone/FEP |

| Jacket | PVC for cost, PUR for abrasion, TPE/TPU for flex & cold |

| Conductor | Stranded, high strand count per IEC Class 5/6 |

| Shielding | Foil+braid for EMI and flexibility |

| Standards | UL, IEC, NEC, RoHS, fire ratings required |

| Performance | Check abrasion, temperature, ampacity, voltage drop |

By considering environment, jacket material, conductor design, shielding, standards, and performance, you ensure long-lasting and reliable industrial-grade flexible cables for harsh operating conditions.