Time: 2025-04-22 13:25:14 Source: Henan Province Jianyun Cable Co., Ltd.

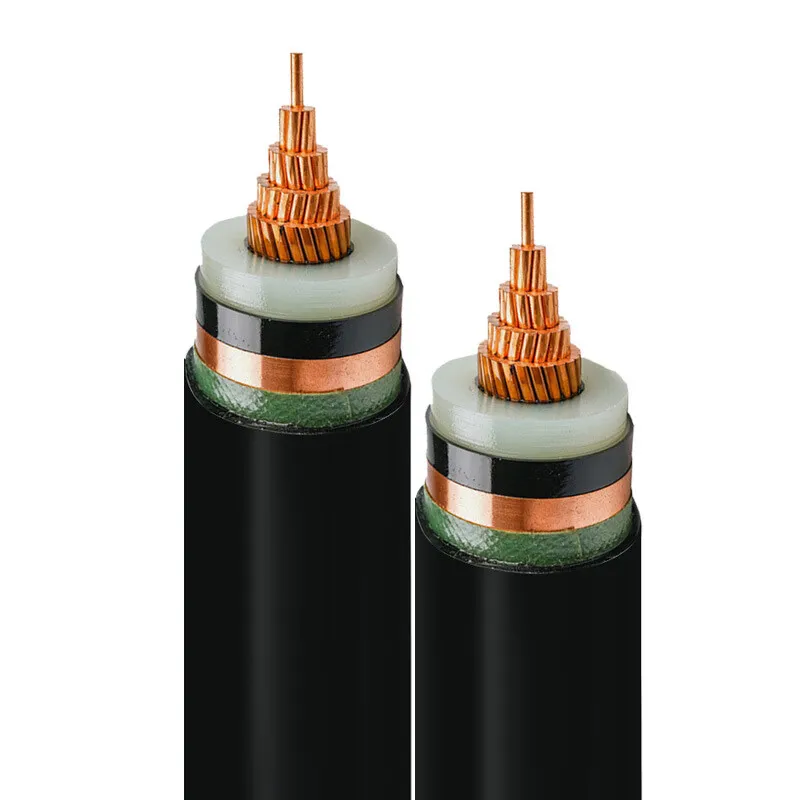

Medium Voltage (MV) Cables: MV cables are designed to operate at voltages between 1 kV and 35 kV, as defined by standards like IEC 60502 or NEC. They are typically used for local power distribution, connecting substations to industrial facilities, commercial buildings, or residential areas. MV cables often feature insulation like XLPE (cross-linked polyethylene) and may include armouring (e.g., STA or SWA, as discussed earlier).

High Voltage (HV) Cables: HV cables operate at voltages above 35 kV, typically ranging from 66 kV to 230 kV, though some definitions include up to 765 kV for extra-high voltage (EHV). They are used for long-distance power transmission, connecting power plants to substations or major grid networks. HV cables require thicker insulation and often use specialized materials to handle higher electrical stresses.

MV cables are like the regional roads of the power grid, distributing electricity within a local area, while HV cables are the major highways, transporting large amounts of power over long distances to feed those regional networks.

MV and HV cables differ in their voltage ratings, construction, insulation, and installation requirements, reflecting their distinct roles in the power grid. Below is a detailed comparison:

| Feature | MV Cables | HV Cables |

|---|---|---|

| Voltage Rating | 1 kV to 35 kV | Above 35 kV (66 kV to 230 kV, up to 765 kV for EHV) |

| Insulation Thickness | Thinner (e.g., 2–5 mm for 11 kV) | Thicker (e.g., 10–20 mm for 132 kV) |

| Conductor Size | Smaller (e.g., 35–400 mm²) | Larger (e.g., 500–2000 mm²) |

| Insulation Material | XLPE or EPR | XLPE with additional shielding layers |

| Shielding | Copper tape or wire shield | Multi-layer shielding (e.g., semiconductor, metallic) |

| Armouring | Optional (e.g., SWA, STA) | Rare, focuses on insulation |

| Installation | Buried, in ducts, or overhead | Often buried or submarine, rarely overhead |

Voltage and Construction: MV cables handle 1–35 kV, requiring less insulation (e.g., 2.5 mm XLPE for 11 kV), while HV cables manage 66–230 kV, needing thicker insulation (e.g., 15 mm for 132 kV) and multi-layer shielding to control electric fields and prevent breakdown. Conductor: HV cables use larger conductors to minimize resistance over long distances, often 1000 mm² or more, compared to MV’s 35–400 mm². Shielding and Armouring: MV cables may use simple copper tape shields and optional armour (e.g., SWA), while HV cables require complex shielding (semiconductor layers, metallic screens) to manage high electric fields, with armouring less common due to underground installation. It’s like comparing a sturdy delivery truck (MV) for local routes to a heavy-duty freight train (HV) for cross-country hauls—one needs basic protection, the other advanced engineering.

MV and HV cables are deployed in different segments of the power grid, reflecting their voltage capacities and construction.

MV cables are versatile, used in both urban and rural settings, often buried in ducts or direct burial with armouring like STA. HV cables, due to their high voltage, are typically buried or submarine to reduce risks, requiring specialized installation like directional drilling for underground runs. MV cables are the local delivery vans of electricity, while HV cables are the long-haul cargo ships, moving massive power loads across vast distances.

MV and HV cables differ primarily in their voltage ratings and construction: MV cables (1–35 kV) use thinner insulation and smaller conductors for local distribution, while HV cables (above 35 kV) feature thicker insulation, larger conductors, and advanced shielding for long-distance transmission. MV cables often include armouring (e.g., SWA) and are used in urban or rural distribution, while HV cables are typically buried or submarine, linking power plants to grids. Understanding these differences ensures the right cable is chosen for safe, efficient power delivery in electrical systems.

Word count: ~600 words

(Note: This article is based on general electrical knowledge and industry standards. For specific applications, consult a professional electrical engineer and follow local codes.)