Four-Core Cables: Applications and Functionality

Time: 2025-05-21 15:42:51

Source: Henan Province Jianyun Cable Co., Ltd.

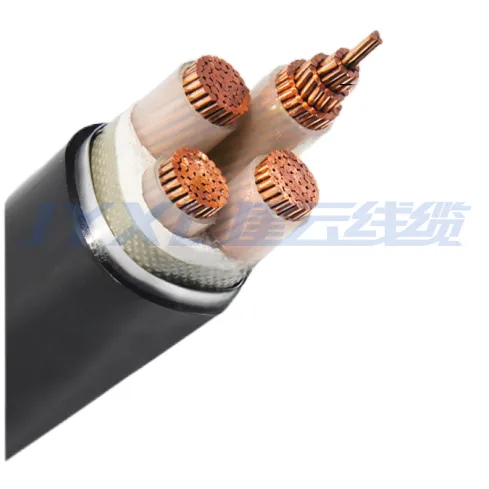

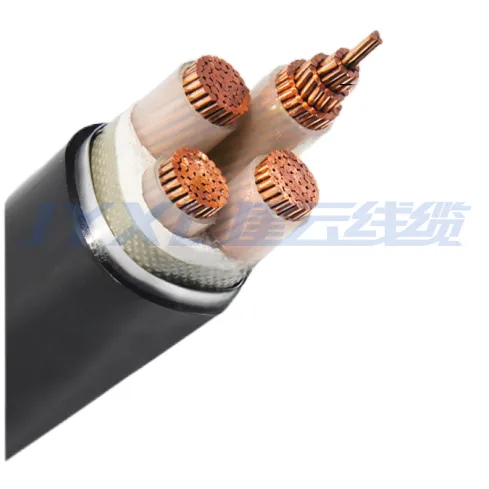

Introduction to Four-Core Cables

A four-core cable is a multiconductor cable containing four individually insulated conductors within a single outer sheath. These cables are designed to transmit electrical power or signals in systems requiring multiple phases or circuits, typically in three-phase power systems with an additional neutral conductor. Four-core cables are widely utilized in various industries for their ability to provide efficient, reliable, and safe power or signal distribution in diverse applications.

Design and Construction

Four-core cables are engineered to meet specific electrical, mechanical, and environmental requirements. Their key components include:

-

Conductors: Typically made of copper or aluminum for high conductivity, the four conductors are arranged to carry three phases and a neutral in power applications or multiple signal channels in control systems.

-

Insulation: Each conductor is insulated with materials such as polyvinyl chloride (PVC), cross-linked polyethylene (XLPE), or ethylene propylene rubber (EPR) to prevent electrical interference and ensure safety.

-

Outer Sheath: A durable jacket, often made of PVC, polyurethane, or low-smoke zero-halogen (LSZH) materials, protects the cable from moisture, chemicals, and mechanical damage.

-

Armor (Optional): In demanding environments, such as underground or industrial settings, a metallic armor layer may be added for enhanced mechanical protection.

-

Filler or Bedding: Non-conductive materials fill the spaces between conductors to maintain cable structure and provide stability.

Primary Applications of Four-Core Cables

Four-core cables are primarily used in systems requiring three-phase power with a neutral conductor or in control and signal applications. Their main applications include:

-

Three-Phase Power Distribution with Neutral: Four-core cables are commonly used in three-phase electrical systems where three conductors carry the phase currents, and the fourth serves as the neutral conductor. This configuration is ideal for powering industrial equipment, commercial buildings, and residential complexes.

-

Industrial Applications: In manufacturing facilities, four-core cables supply power to heavy machinery, motors, and pumps, where three-phase power ensures efficient operation, and the neutral conductor supports balanced loads or single-phase circuits.

-

Utility Networks: Electric utilities use four-core cables in low- and medium-voltage distribution networks, often in underground or aerial installations, to deliver power to substations, commercial properties, or residential areas.

-

Building Management Systems: Four-core cables are employed in HVAC, lighting, and other building systems, providing power and control signals to ensure efficient operation.

-

Renewable Energy Systems: In solar and wind power installations, four-core cables connect inverters to the grid, supporting three-phase power transmission with a neutral for balanced power delivery.

-

Control and Instrumentation Systems: In automation and monitoring systems, four-core cables can transmit multiple control signals or data channels, supporting complex control circuits in industrial or utility applications.

-

Marine and Offshore Applications: Four-core cables are used in ships and offshore platforms to power critical systems, with designs tailored to withstand harsh marine environments.

Advantages of Four-Core Cables

Four-core cables offer several benefits that make them suitable for their applications:

-

Efficiency in Three-Phase Systems: The inclusion of a neutral conductor allows for balanced power distribution and supports single-phase loads within a three-phase system, enhancing efficiency.

-

Compact Design: Combining four conductors in a single cable simplifies installation and reduces space requirements compared to using multiple single-core cables.

-

Versatility: Suitable for both power and control applications, four-core cables can be tailored to various voltage ratings and environmental conditions.

-

Durability: Robust insulation and sheathing ensure reliable performance in challenging environments, such as industrial plants or outdoor installations.

Challenges and Considerations

While four-core cables are highly effective, certain challenges must be addressed:

-

Installation Complexity: Proper installation is essential to avoid phase imbalance, mechanical stress, or incorrect termination, particularly in aerial or underground setups.

-

Environmental Exposure: Cables exposed to moisture, extreme temperatures, or chemicals require appropriate sheathing or armor to prevent degradation.

-

Electromagnetic Interference (EMI): In control or signal applications, shielding may be necessary to protect against EMI and ensure signal integrity.

To address these challenges, four-core cables are designed to comply with industry standards, such as those established by organizations like the Association of Edison Illuminating Companies (AEIC), ensuring performance, safety, and compatibility with utility systems.

Installation and Maintenance

Proper installation and maintenance are critical for the performance of four-core cables:

-

Installation: Cables must be installed with appropriate tension and support in aerial applications or with proper protection in underground setups to prevent damage. Correct phase and neutral connections are essential for system balance.

-

Termination and Jointing: Accurate termination to equipment or junction boxes ensures reliable power or signal transmission, with proper labeling to avoid connection errors.

-

Maintenance: Regular inspections for insulation wear, corrosion, or physical damage help prevent failures. Testing for phase balance, insulation resistance, and continuity can identify potential issues.

Future Trends

As electrical and control systems advance, four-core cables are evolving to meet new requirements:

-

Smart Grid Compatibility: Four-core cables are being optimized for smart grid applications, supporting real-time monitoring and control in advanced power networks.

-

Sustainable Materials: Eco-friendly insulation and sheathing materials are being adopted to reduce environmental impact.

-

Higher Voltage Capabilities: Advances in insulation technology are enabling four-core cables to handle higher voltages for renewable energy and long-distance transmission.

-

Automation and IoT Integration: In control applications, four-core cables are being designed to support Internet of Things (IoT) devices and automated systems with enhanced signal reliability.

Conclusion

Four-core cables are essential components in three-phase power distribution and control systems, offering efficient and reliable performance across industrial, utility, and renewable energy applications. Their ability to combine three-phase power with a neutral conductor in a compact, durable design makes them versatile and widely used. As technology progresses, four-core cables will continue to play a critical role in supporting modern electrical and communication networks, adapting to the demands of smart, sustainable, and efficient systems.