Flat Cable vs. Round Cable: Key Differences

Time: 2025-05-14 13:53:53

Source: Henan Province Jianyun Cable Co., Ltd.

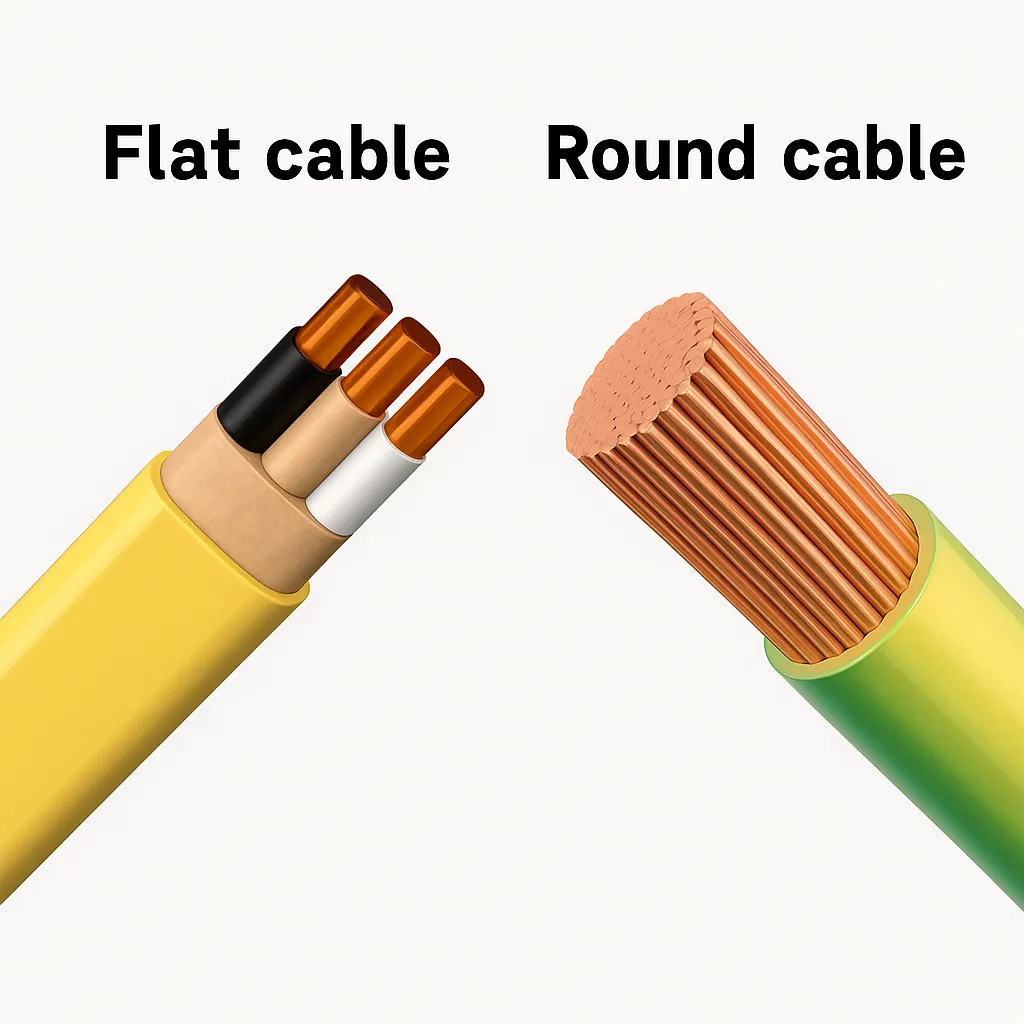

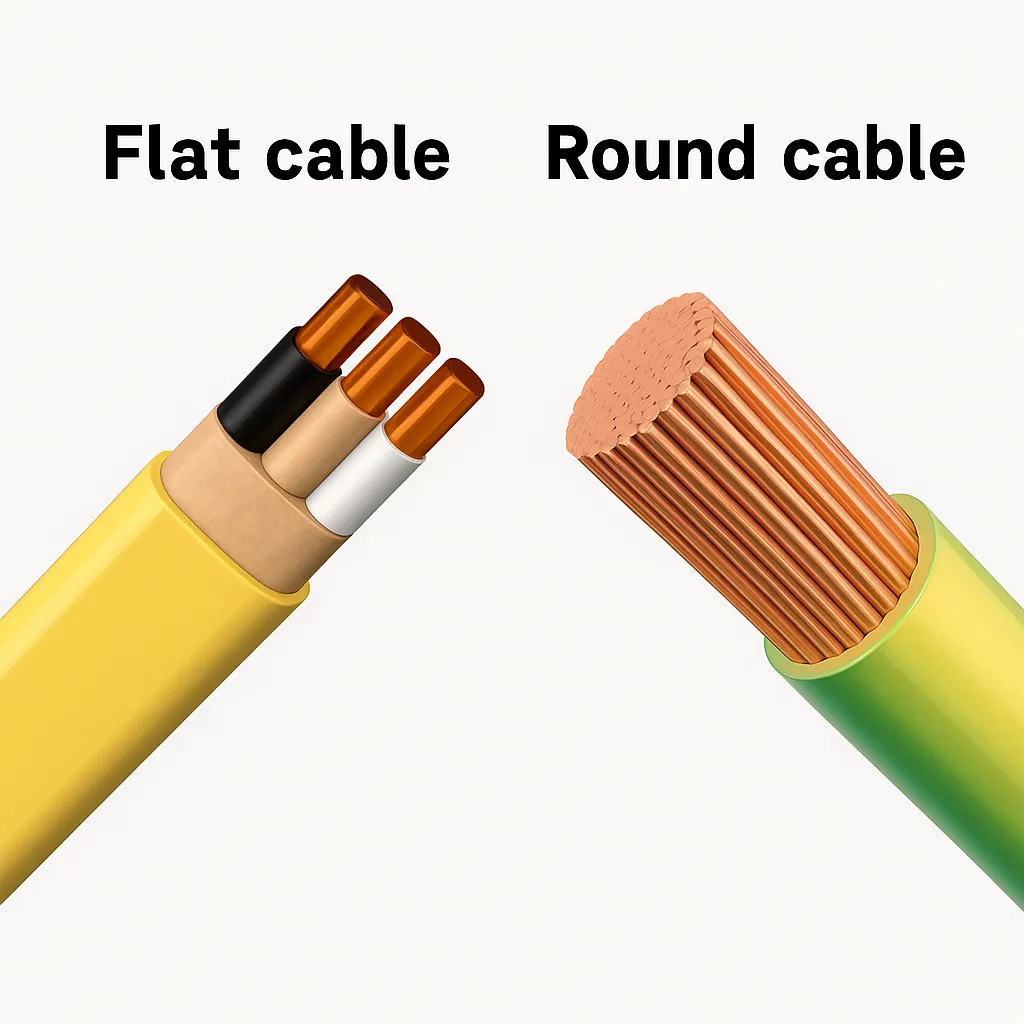

What Are Flat and Round Cables?

Flat and round cables are two common types of cables used for power and data transmission, widely applied in network wiring, industrial equipment, and consumer electronics. Flat cables feature a thin, wide, ribbon-like structure with conductors arranged side by side, ideal for space-constrained or high-flexibility scenarios. Round cables have a traditional cylindrical design with conductors twisted or stranded in a circular configuration, suited for long-distance transmission and harsh environments. Both comply with international standards such as IEC 60228, UL, or TIA/EIA-568, supporting Ethernet (Cat5e to Cat8), power transmission, or control circuits. They are similar to cables like THHN, H07RN-F, or 6 AWG wires discussed previously, but differ in design and application. Selecting the appropriate cable type requires evaluating installation conditions, performance needs, and maintenance requirements.

Construction and Specifications

Flat and round cables differ significantly in construction, impacting their performance and suitability:

-

Flat Cable:

-

Conductor: Multiple fine copper strands (e.g., 32 AWG), arranged side by side in a ribbon, typically unshielded (UTP), with Cat7 and Cat8 offering shielding (STP).

-

Insulation: PVC or Flexx-Sil™ rubber ensures consistent electrical properties, reducing signal skew, similar to LSOH or silicone cables.

-

Jacket: Thin, wide thermoplastic material without fillers, lightweight (50% less than round cables), and conducive to heat dissipation.

-

Specifications: Supports Cat6 to Cat8, with data rates up to 10 Gbps, typically limited to 30–50 meters, and a small bending radius (about 2x thickness).

-

Round Cable:

-

Conductor: Solid or stranded copper (24–26 AWG), twisted into a circular shape, enhancing tensile strength, similar to 6 AWG or multi-conductor cables.

-

Insulation: PVC or polyethylene with fillers (e.g., textile wraps) to maintain round shape, reducing frictional heat, similar to THHN or RHW wires.

-

Jacket: Thick PVC or polyurethane, often with shielding (STP) to minimize electromagnetic interference (EMI), similar to H07RN-F or marine cables.

-

Specifications: Supports Cat5e to Cat8, with transmission distances up to 100 meters, rated for 600V, and resistant to multi-axis mechanical stress (e.g., torsion).

Flat cables prioritize space efficiency and flexibility, while round cables emphasize durability and long-distance transmission, akin to the contrast between trailing cables and household wires discussed previously.

Key Differences Between Flat and Round Cables

The design and performance differences between flat and round cables determine their suitability for specific applications. Below are seven key distinctions:

-

Shape and Space Usage: Flat cables are thin and ribbon-like, occupying 50% less space than round cables, ideal for tight spaces; round cables are bulkier but easier to coil and pull through conduits.

-

Flexibility: Flat cables are highly flexible along a single axis (rolling bends), suitable for compact bending; round cables support multi-axis bending (e.g., twisting) but are stiffer in confined spaces.

-

Electromagnetic Interference (EMI) Protection: Round cables offer better EMI protection due to twisted pairs and shielding (STP); flat cables are often unshielded, making them susceptible to interference, especially over long distances.

-

Heat Dissipation: Flat cables have a larger surface area, providing superior heat dissipation for high-current applications; round cables dissipate heat less efficiently due to layered fillers, requiring low-friction materials.

-

Signal Integrity: Flat cables maintain consistent electrical length across parallel conductors, minimizing signal skew; round cables reduce crosstalk through twisting but may have variable conductor spacing.

-

Installation Ease: Flat cables are easily laid along walls or under carpets, ideal for temporary or aesthetic wiring; round cables are better for wall penetrations or long-distance fixed installations.

-

Cost: Flat cables are 10–20% cheaper due to the absence of fillers and shielding; round cables are more expensive due to complex construction and materials.

These differences mirror trade-offs discussed in PUR vs. PVC or THHN vs. THWN cables, requiring careful consideration of application needs.

Applications of Flat and Round Cables

Flat and round cables serve distinct applications based on their characteristics:

-

Flat Cable:

-

Consumer Electronics: Used for internal connections in laptops, tablets, and smartphones, saving space, similar to silicone or flexible cables.

-

Home and Office: Run along walls or under carpets (e.g., Cat6 flat Ethernet cables) for aesthetic and manageable wiring, similar to NM or UF cables.

-

Robotics and Aerospace: High flexibility and low weight suit dynamic motion equipment, similar to trailing or H07RN-F cables.

-

Medical Devices: Compact design fits internal wiring in precision instruments, similar to multi-conductor or low-smoke halogen-free cables.

-

Round Cable:

-

Data Centers: Cat6 to Cat8 round cables support long-distance, high-speed transmission with EMI resistance, similar to 6 AWG or MV cables.

-

Industrial Settings: Used in automation equipment, motors, and control systems, withstanding mechanical and environmental stress, similar to H07RN-F or RHW cables.

-

Building Wiring: Installed through walls or conduits (e.g., Cat6 round cables) for structured cabling, similar to THHN or household wires.

-

Outdoor Applications: Thick insulation and shielding support wiring in harsh environments, similar to marine or trailing cables.

Flat cables excel in space-constrained and short-term wiring, while round cables are ideal for high-reliability and long-distance applications.

Maintenance and Durability

Flat and round cables differ significantly in maintenance needs and durability:

-

Flat Cable: Lacking shielding and fillers, they are prone to physical damage and EMI, requiring regular inspections, especially in high-interference environments. Repairs are complex, involving jacket stripping, increasing downtime. Lifespan (about 5–10 years) is shorter than round cables, similar to PUR or flexible cables.

-

Round Cable: Thick insulation and shielding enhance durability, resisting bending, twisting, and environmental stress (e.g., UV, oil), with a lifespan of 15–20 years. Repairs are simpler, involving splicing or replacing faulty segments, similar to H07RN-F or 6 AWG cables.

Round cables are more reliable in high-stress environments, while flat cables suit low-maintenance, short-term applications.

Flat vs. Round Cable Comparison Table

The table below summarizes the key characteristics of flat and round cables:

|

Feature

|

Flat Cable

|

Round Cable

|

|

Conductor

|

Parallel multi-strand copper (32 AWG)

|

Twisted copper (24–26 AWG)

|

|

Insulation

|

PVC/Flexx-Sil™, no fillers

|

PVC/Polyethylene, with fillers

|

|

Jacket

|

Thin thermoplastic

|

Thick PVC/Polyurethane, with shielding

|

|

Transmission Distance

|

30–50 meters

|

Up to 100 meters

|

|

Flexibility

|

High (single-axis bending)

|

Moderate (multi-axis bending)

|

|

EMI Protection

|

Weak (mostly UTP)

|

Strong (STP)

|

|

Heat Dissipation

|

Excellent (large surface area)

|

Moderate (layered fillers)

|

|

Cost

|

Lower

|

Higher

|

|

Applications

|

Consumer electronics, short-distance wiring

|

Data centers, industrial, long-distance

|

Note: Performance based on Cat6 Ethernet cables and NEC/IEC standards. Verify specific applications with TIA/EIA-568 or AS/NZS 5000 standards.

Tips for Choosing Flat or Round Cables

Selecting the right cable involves considering the following factors:

-

Evaluate Installation Environment: Choose flat cables for tight spaces or aesthetic wiring (e.g., under carpets); select round cables for long distances or high-EMI settings (e.g., data centers), similar to THHN vs. THWN choices.

-

Determine Transmission Needs: Use flat Cat6 cables for short distances (<50 meters) or low-speed networks; opt for round Cat6a/Cat7 cables for long distances (≤100 meters) or high-speed networks (e.g., 10 Gbps).

-

Consider Flexibility and Mechanical Stress: Select flat cables for single-axis bending or dynamic applications; choose round cables for multi-axis stress (e.g., torsion), similar to trailing or H07RN-F cables.

-

Check Shielding Needs: Use round STP cables in high-EMI environments (e.g., industrial plants); flat UTP cables suffice in low-interference settings (e.g., homes).

-

Budget and Maintenance: Choose flat cables for budget-conscious or short-term use; select round cables for long-term durability and low maintenance, similar to 6 AWG or RHW cables.

-

Verify Standards: Ensure compliance with IEC 60228, TIA/EIA-568, or UL standards, similar to LSOH or H07RN-F cable requirements.

-

Consult Professionals: Confirm cable specifications (e.g., Cat6 vs. Cat7, shielding needs) with electricians or manufacturers to ensure compliant installation.

These steps optimize cable selection for performance and cost, akin to choosing household or multi-conductor cables discussed previously.

Conclusion

Flat and round cables each offer distinct advantages, addressing diverse wiring needs. Flat cables excel in space efficiency, high flexibility, and low cost, making them ideal for consumer electronics, home wiring, and compact devices, similar to the flexibility of PUR or silicone cables. Round cables, with their durability, superior EMI protection, and long-distance transmission capabilities, are preferred for data centers, industrial settings, and structured cabling, akin to the reliability of H07RN-F or 6 AWG cables. Selection requires balancing installation environment, transmission distance, shielding needs, and maintenance costs, while ensuring compliance with NEC, IEC, or TIA/EIA standards. Through proper selection and professional installation, both flat and round cables deliver efficient, reliable power or data transmission, building on the utility of cables like THHN, H07RN-F, or trailing cables discussed previously.