Comprehensive Comparison: Copper (CU) vs. Aluminum (AL) Cables

Time: 2025-05-07 01:08:16

Source: Henan Province Jianyun Cable Co., Ltd.

Introduction

In electrical installations, selecting the appropriate conductor material is crucial for ensuring safety, efficiency, and cost-effectiveness. The two most commonly used conductor materials are:

-

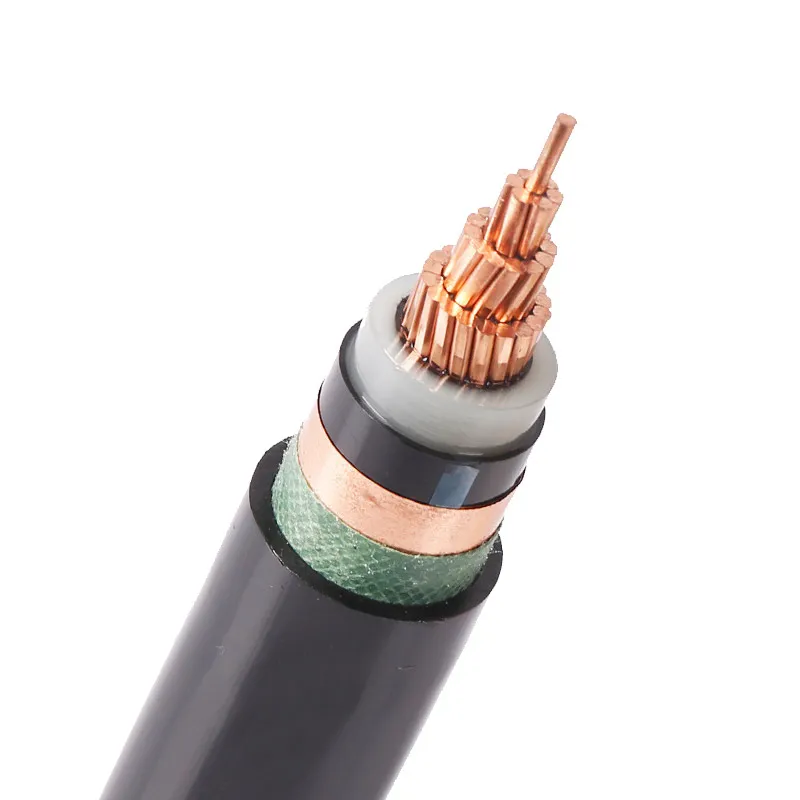

Copper (CU): Known for its excellent electrical conductivity and mechanical strength.

-

Aluminum (AL): Valued for its lightweight and cost-effectiveness.

Understanding the differences between these two materials is essential for making informed decisions in various electrical applications.

Electrical Properties

Copper (CU)

-

Conductivity: Copper has a high electrical conductivity of approximately 5.96 × 107 S/m, making it the standard for electrical conductors.

-

Resistance: Lower electrical resistance leads to reduced energy losses and better performance over long distances.

-

Thermal Expansion: Copper has a lower coefficient of thermal expansion, resulting in more stable connections under varying temperatures.

Aluminum (AL)

-

Conductivity: Aluminum's conductivity is about 61% that of copper, necessitating larger cross-sectional areas to carry the same current.

-

Resistance: Higher resistance can lead to increased energy losses and potential overheating if not properly managed.

-

Thermal Expansion: Aluminum expands more with temperature changes, which can loosen connections over time if not properly installed.

-

Mechanical Characteristics

Copper (CU)

-

Strength: Higher tensile strength makes copper more durable and less prone to breakage.

-

Flexibility: More flexible, facilitating easier installation, especially in tight spaces.

-

Corrosion Resistance: Excellent resistance to corrosion, ensuring longevity.

Aluminum (AL)

-

Strength: Lower tensile strength, making it more susceptible to damage during installation.

-

Flexibility: Less flexible, which can complicate installation in certain scenarios.

-

Corrosion Resistance: Prone to oxidation, which can affect conductivity; requires antioxidant compounds at connections.

Cost and Weight

Copper (CU)

-

Cost: Significantly more expensive due to material costs.

-

Weight: Heavier, which can increase structural support requirements and transportation costs.

Aluminum (AL)

-

Cost: More cost-effective, making it attractive for large-scale projects.

-

Weight: Approximately one-third the weight of copper, reducing structural and transportation burdens.

Applications

Copper (CU)

-

Residential wiring

-

High-performance industrial applications

-

Situations requiring high reliability and minimal maintenance

Aluminum (AL)

-

Utility and power distribution

-

Overhead transmission lines

-

Large-scale industrial projects where weight and cost are critical factors

Technical Comparison Table

|

Feature

|

Copper (CU)

|

Aluminum (AL)

|

|

Electrical Conductivity

|

High (5.96 × 107 S/m)

|

Moderate (3.5 × 107 S/m)

|

|

Tensile Strength

|

High

|

Lower

|

|

Flexibility

|

More flexible

|

Less flexible

|

|

Corrosion Resistance

|

Excellent

|

Requires protective measures

|

|

Cost

|

Higher

|

Lower

|

|

Weight

|

Heavier

|

Lighter

|

|

Typical Applications

|

Residential, high-reliability installations

|

Power distribution, large-scale industrial

|

Conclusion

Selecting between copper and aluminum cables hinges on specific project requirements:

-

Choose Copper (CU) when:

-

High conductivity and reliability are paramount.

-

Space constraints demand smaller conductor sizes.

-

Long-term durability with minimal maintenance is desired.

-

Choose Aluminum (AL) when:

-

Budget constraints are significant.

-

Weight reduction is essential, such as in overhead lines.

-

Large-scale installations where cost-effectiveness is prioritized.

Proper installation and maintenance are crucial for both types to ensure safety and performance.