Current Technological Status and Development Trends of China's Cable Industry

Time: 2025-03-14 15:38:10

Source: Henan Province Jianyun Cable Co., Ltd.

Introduction

The cable industry is a vital sector supporting the national economy, playing a critical role in power transmission, communication, and industrial automation. With over 7,000 cable manufacturers and a total output value of 1.64 trillion RMB, China's cable industry ranks second in the machinery manufacturing sector. However, technological advancements and material innovations are necessary to enhance product performance and meet global competition.

This article provides an in-depth analysis of the current status and future trends of China's cable industry, focusing on:

-

Power cables

-

Equipment cables

-

Winding wires

-

Communication cables

-

Conductor materials and overhead transmission lines

-

High-performance materials like carbon fiber, copper-graphene composites, and aluminum-carbon nanotubes

1. Technological Status of Power Cables

1.1 Insulation Materials Localization

-

110 kV cross-linked polyethylene (XLPE) insulation material has been successfully mass-produced domestically.

-

220 kV and 330 kV insulation materials have entered pilot application stages.

-

Low-smoke, halogen-free flame-retardant materials and fire-resistant materials have been improved for better electrical and mechanical performance.

1.2 Advanced Production Equipment

-

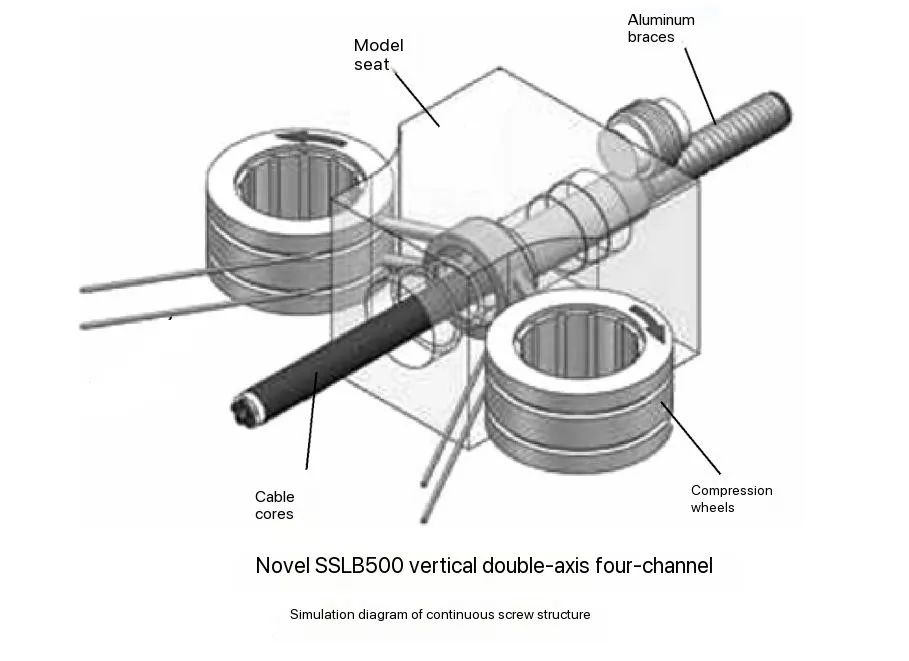

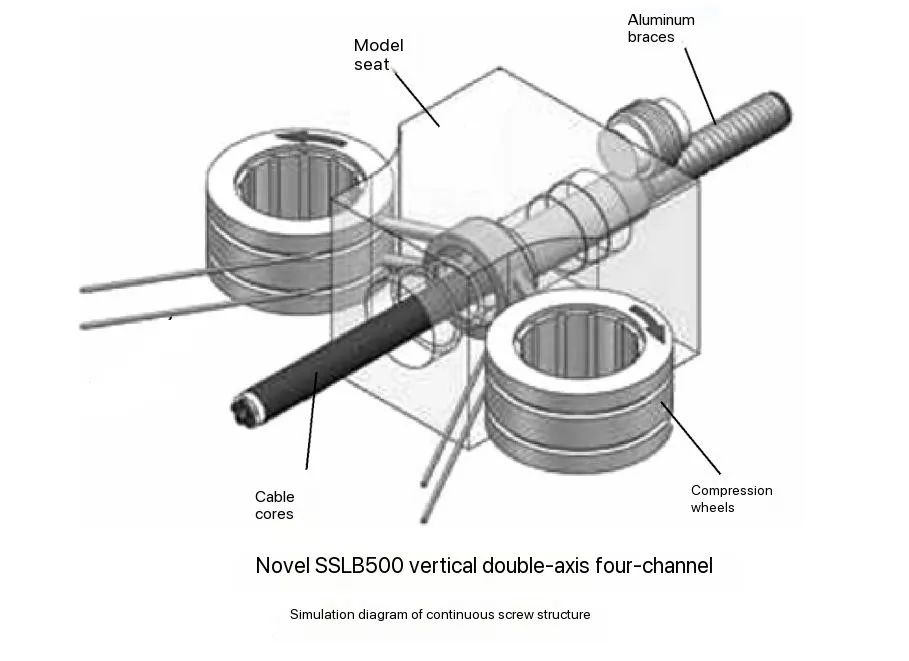

The SSLB500 vertical double-axis continuous extrusion machine has been developed, achieving high-efficiency production of smooth aluminum sheaths for high-voltage cables (up to 500 kV).

-

The continuous extrusion process improves aluminum sheath quality, reducing material waste by 10%.

1.3 High-Performance Power Cable Products

|

Type of Cable

|

Technological Progress

|

Voltage Level

|

|

Polypropylene Insulated Cable

|

Mass production in power grids

|

Up to 110 kV

|

|

Submarine Cable

|

Extended length, higher voltage

|

Up to 500 kV

|

|

Dynamic Submarine Cable

|

For offshore wind farms

|

35-66 kV

|

|

High-Temperature Superconducting Cable

|

Industrial application in Shanghai

|

35 kV

|

2. Equipment Cables: Current Situation and Trends

-

Low-smoke, halogen-free flame-retardant cables have become mainstream in rail transit and nuclear power plants.

-

Photovoltaic cables, wind power cables, and electric vehicle charging cables are growing rapidly.

-

High-performance materials like fluoropolymers and silicone rubber are replacing imported materials for better heat and chemical resistance.

3. Winding Wires: Technological Innovations

-

Aluminum winding wires are increasingly replacing copper due to cost efficiency and lighter weight.

-

High-temperature winding wires (up to 400°C) are being developed for advanced electric motors and transformers.

-

Litz wire technology is being used in superconducting coils and high-speed maglev systems.

4. Communication Cables: Leading the Global Market

-

China holds the world's largest optical fiber and cable production capacity, with 50% global market share.

-

Advanced optical fiber composite cables (OPGW and ADSS) are widely used in power grids and industrial networks.

-

Deep-sea communication cables with higher transmission capacity and longer distances are under development.

5. Conductor Materials and Overhead Transmission Lines

5.1 High-Conductivity Copper and Aluminum Materials

-

Fire-refined high-conductivity copper (FRHC) has achieved 99.90% copper purity with 100% IACS conductivity.

-

High-strength aluminum alloy conductors (Al-Mg-Si alloy) with 57.5% IACS conductivity are being developed for overhead transmission lines.

5.2 Emerging Materials

|

Material

|

Advantages

|

Application

|

|

Copper-Graphene Composite

|

High conductivity and strength

|

High-voltage cables

|

|

Aluminum-Carbon Nanotube Composite

|

Lightweight and durable

|

Overhead power lines

|

|

Ultra-Pure Copper-Silver Alloy

|

High tensile strength

|

Aerospace cables

|

6. High-Performance Carbon Fiber in the Cable Industry

-

Carbon fiber composite cores are used in high-voltage overhead lines, replacing steel cores to reduce weight and increase current capacity.

-

Submarine cables with carbon fiber reinforcement improve strength and corrosion resistance.

-

Carbon fiber is also used in deep-sea oil exploration cables and high-speed rail communication systems.

7. Future Trends and Challenges

7.1 Smart and Green Cable Technology

-

Digital monitoring systems for cable health detection

-

Smart grid-compatible cables for renewable energy transmission

-

Recyclable and eco-friendly insulation materials

7.2 Industrialization Challenges

-

Copper-Graphene and Aluminum-Carbon Nanotube composites face difficulty in mass production due to material dispersion and stability issues.

-

Continuous production lines for superconducting cables require further equipment innovation and cost reduction.

Conclusion

China's cable industry has made significant progress in material innovation, production equipment, and high-performance cable development. However, global competition and the demand for green energy solutions require further breakthroughs in advanced materials and intelligent manufacturing technologies.

Keywords

-

Power Cables

-

High-Performance Carbon Fiber

-

Copper-Graphene Composite

-

Aluminum-Carbon Nanotube Conductor

-

Superconducting Cables

-

Smart Grid Technology

References

-

Huang Chongqi, Xu Xiaofeng, Liu Jingping, Li Fu, Gao Huan (2024). Technical Status and Development Trend of Cable Industry in China. Wire & Cable, No.6, 2024. DOI: 10.16105/j.dxdl.1672-6901.202406001

-

GB/T 12706-2020 – Standard for Power Cable Testing

-

GB/T 20141-2021 – Standard for Optical Fiber Cable Manufacturing