Cable Voltage Ratings Explained: LV, MV, HV Differences

Time: 2025-06-10 15:10:43

Source: Henan Province Jianyun Cable Co., Ltd.

Table of Contents

Introduction

Electrical cables are classified based on their voltage ratings to ensure safe and efficient power distribution. Understanding the differences between Low Voltage (LV), Medium Voltage (MV), and High Voltage (HV) cables is crucial for selecting the appropriate cable type for specific applications. This article explores the characteristics, construction, and applications of each cable type.

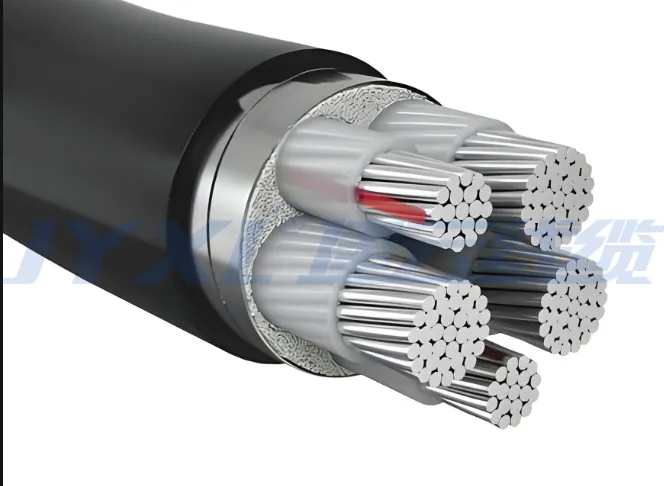

Low Voltage (LV) Cables

Low Voltage (LV) cables are designed to operate at voltages up to 1,000 volts. They are commonly used in residential, commercial, and light industrial applications.

-

Voltage Rating: Up to 1,000 V

-

Common Applications: Residential wiring, lighting circuits, small motors, and appliances

-

Construction: Typically consist of copper or aluminum conductors with PVC or XLPE insulation and a protective sheath

-

Standards: Comply with international standards such as IEC 60227 and IEC 60228

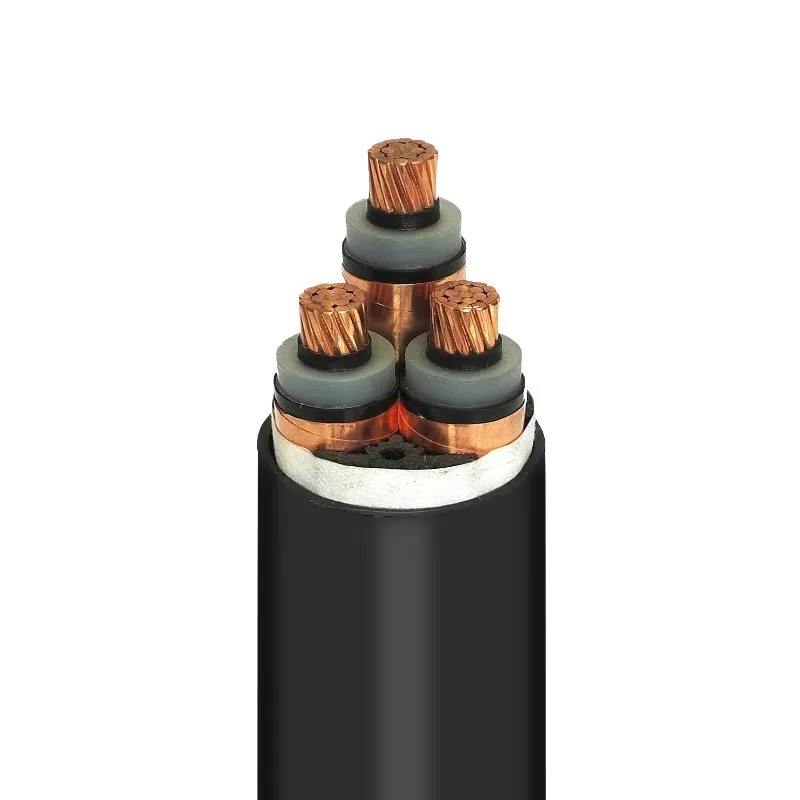

Medium Voltage (MV) Cables

Medium Voltage (MV) cables operate within the voltage range of 1 kV to 35 kV. They are used for power distribution in industrial plants, substations, and utility networks.

-

Voltage Rating: 1 kV to 35 kV

-

Common Applications: Industrial power distribution, substation connections, and renewable energy systems

-

Construction: Feature multiple layers including conductor, insulation, metallic sheath, and outer sheath for mechanical protection

-

Standards: Adhere to standards like IEC 60502 and IEC 60840

High Voltage (HV) Cables

High Voltage (HV) cables are designed for voltages above 35 kV, extending up to 550 kV or more. They are primarily used for long-distance power transmission.

-

Voltage Rating: Above 35 kV

-

Common Applications: Transmission lines, interconnection of power grids, and connection between power plants and substations

-

Construction: Comprised of several layers including conductor, insulation, metallic sheath, and protective outer sheath, with additional layers for water blocking and mechanical protection

-

Standards: Conform to standards such as IEC 60840 and IEC 62067

Voltage Rating Comparison Table

|

Voltage Range

|

Common Applications

|

Typical Insulation Materials

|

Standards

|

|

Up to 1,000 V

|

Residential and commercial wiring

|

PVC, XLPE

|

IEC 60227, IEC 60228

|

|

1 kV to 35 kV

|

Industrial power distribution, substations

|

XLPE, EPR

|

IEC 60502, IEC 60840

|

|

Above 35 kV

|

Transmission lines, power grid interconnections

|

XLPE, EPR, oil-impregnated paper

|

IEC 60840, IEC 62067

|

Applications of LV, MV, and HV Cables

The selection of cable voltage rating depends on the specific requirements of the electrical system:

-

LV Cables: Suitable for short-distance power distribution, connecting electrical appliances and lighting systems in residential and commercial buildings.

-

MV Cables: Ideal for medium-distance power distribution, connecting substations to local distribution networks and supplying power to industrial facilities.

-

HV Cables: Essential for long-distance power transmission, linking power generation stations to substations and enabling interconnection between different power grids.

Conclusion

Understanding the differences between LV, MV, and HV cables is vital for ensuring the safe and efficient design of electrical systems. Proper selection based on voltage ratings, construction, and application requirements helps in optimizing performance and adhering to safety standards.