Characteristics and Applications of Copper Conductors in Electrical Cables

Time: 2025-05-26 16:00:53

Source: Henan Province Jianyun Cable Co., Ltd.

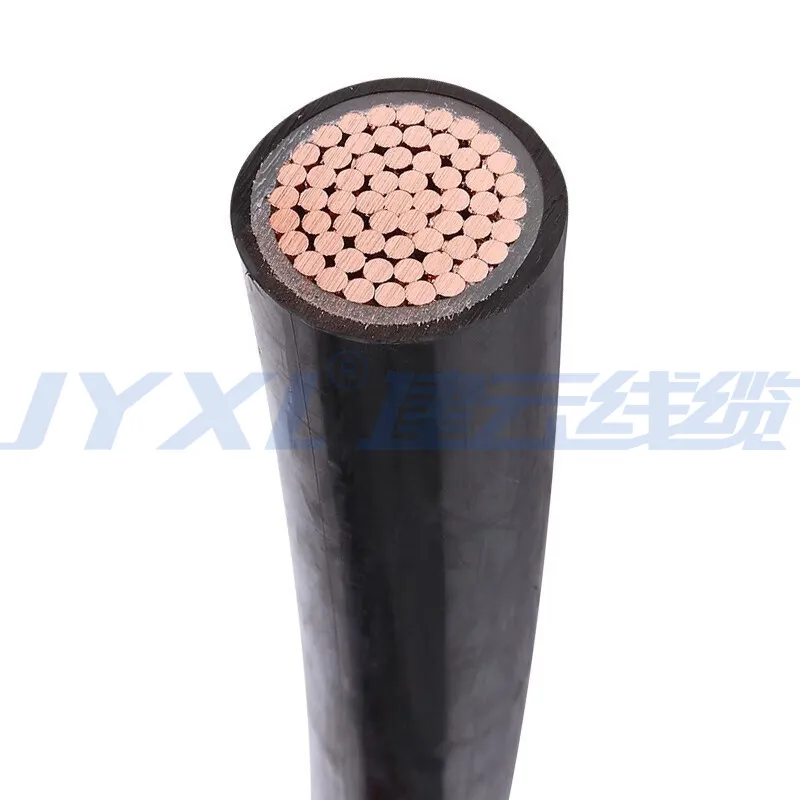

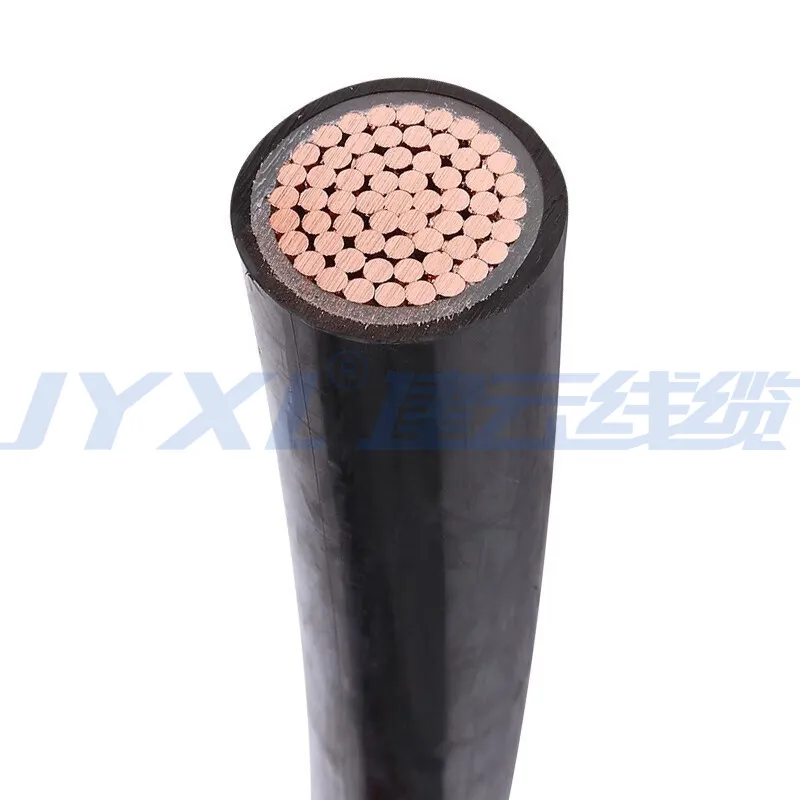

Overview of Copper Conductors

Copper conductors are the core components of electrical cables, responsible for transmitting electric current in power distribution, signal transmission, and control systems. Renowned for their high conductivity and durability, copper conductors are widely used in residential, commercial, industrial, and utility applications. They are available in various forms, such as solid, stranded, or flexible configurations, tailored to specific electrical and environmental requirements. Jianyun Cable Co., based in Luoyang, China, is a leading manufacturer of copper conductor cables, offering solutions that align with global electrical needs, as discussed in prior articles on conductor cables, custom cables, and XLPE insulation.

Properties of Copper Conductors

Copper conductors possess several key properties that make them ideal for electrical applications:

-

High Electrical Conductivity: Copper offers superior electrical conductivity, with a benchmark of 100% on the International Annealed Copper Standard (IACS), ensuring minimal energy loss during transmission, as explored in conductor cable discussions.

-

Low Resistance: Conductors are designed with specific cross-sectional areas (e.g., 0.5 mm² to 3,500 mm²) to maintain low resistance, typically measured in ohms per kilometer, optimizing current flow.

-

Thermal Conductivity: Copper efficiently dissipates heat, preventing hotspots during high-current or overload conditions, enhancing safety in cables like TR-XLPE.

-

Corrosion Resistance: Copper’s conductive oxides maintain electrical performance at connections, unlike aluminum, as noted in armored cable articles.

-

Mechanical Strength: Copper withstands mechanical stress, maintaining integrity during installation or operation, similar to requirements for RW90 cables.

These properties ensure copper conductors deliver reliable and efficient performance.

Classifications of Copper Conductors

Copper conductors are classified based on their construction and flexibility to suit various applications:

-

Class 1 (Solid Conductors): Single, solid copper wires, typically 0.5–16 mm², used in fixed installations like building wiring due to their rigidity and low resistance, as in T90 cables.

-

Class 2 (Stranded Conductors): Multiple copper wires stranded together, offering moderate flexibility for fixed installations, used in power cables like RW90 or TR-XLPE, with cross-sections up to 3,500 mm².

-

Class 5 (Flexible Conductors): Fine copper wires bundled for high flexibility, ideal for movable equipment or control cables, similar to SY cables, with cross-sections from 0.5–400 mm².

-

Class 6 (Highly Flexible Conductors): Very fine wires for maximum flexibility, used in applications requiring frequent bending, such as robotics or portable tools.

Each class is designed with specific resistance values and wire counts to ensure compatibility with intended uses, as discussed in AWG and multi-core cable articles.

Jianyun Cable’s Copper Conductor Cables

Jianyun Cable Co. offers a diverse range of copper conductor cables, tailored to various applications:

-

Low Voltage Power Cables: Copper conductors with XLPE or PVC insulation (up to 1kV) for residential and commercial wiring, akin to RW90 or T90 cables.

-

Medium Voltage Power Cables: Stranded copper conductors (1–35kV) with XLPE insulation for industrial distribution, similar to TR-XLPE or RWU90.

-

Control Cables: Multi-core copper conductors (300/500V) with flexible or stranded designs, used in automation, comparable to SY cables.

-

Armored Cables: Copper conductors with steel or aluminum armor for enhanced protection, as detailed in armored cable discussions.

-

Specialty Cables: Copper-based solar cables or fire-resistant cables, customized for specific environments, as explored in custom cable articles.

Jianyun’s advanced manufacturing ensures high-quality copper conductors for global projects.

Advantages of Copper Conductors

Copper conductors offer several benefits, making them a preferred choice:

-

Superior Conductivity: High IACS rating ensures efficient power transmission, reducing energy losses, as seen in TR-XLPE or RW90 cables.

-

Compact Design: Lower resistance allows smaller cross-sections, reducing insulation and sheathing material, ideal for space-constrained installations.

-

Durability: Resistance to corrosion and mechanical stress extends cable lifespan, similar to armored or RWU90 cables.

-

Safety: High thermal conductivity and melting point prevent overheating, enhancing safety in high-load applications.

-

Versatility: Suitable for fixed, flexible, or high-flex applications, as in control or solar cables.

These advantages align with Jianyun’s high-performance cable offerings.

Applications of Copper Conductor Cables

Copper conductor cables are used across diverse sectors:

-

Residential Wiring: Solid or stranded copper conductors in low voltage cables (e.g., T90, RW90) power homes, supporting lighting and appliances.

-

Industrial Facilities: Medium voltage cables with copper conductors (e.g., TR-XLPE) supply machinery, while flexible control cables manage automation.

-

Underground Utilities: Copper conductors in moisture-resistant cables (e.g., RWU90) ensure reliable power distribution in urban networks.

-

Renewable Energy: Copper-based solar cables with UV-resistant insulation connect photovoltaic systems, as discussed in solar cable articles.

-

Commercial Buildings: Copper conductors in power and control cables support HVAC, lighting, and data systems, similar to SY or custom cables.

-

Portable Equipment: Highly flexible copper conductors in Class 5 or 6 cables power tools or robotics, requiring frequent movement.

These applications highlight copper conductors’ critical role in electrical infrastructure.

Summary of Copper Conductor Types

The table below summarizes copper conductor types and their applications:

|

Conductor Class

|

Key Features

|

Applications

|

|

Class 1 (Solid)

|

Single wire, 0.5–16 mm²

|

Fixed installations, building wiring

|

|

Class 2 (Stranded)

|

Multiple wires, up to 3,500 mm²

|

Power distribution, industrial cables

|

|

Class 5 (Flexible)

|

Fine wires, 0.5–400 mm²

|

Control cables, movable equipment

|

|

Class 6 (Highly Flexible)

|

Very fine wires, 0.5–400 mm²

|

Robotics, portable tools

|

Tips for Selecting Copper Conductor Cables

Choosing the right copper conductor cable ensures optimal performance:

-

Assess Application Type: Use solid conductors for fixed installations or flexible conductors for movable equipment, as in T90 or SY cable discussions.

-

Determine Voltage and Load: Select cross-sectional areas based on current capacity (e.g., 2 AWG for 115A), as explored in AWG articles.

-

Evaluate Environmental Conditions: Choose cables with XLPE or PVC insulation for moisture or UV resistance, akin to RWU90 or solar cables.

-

Consider Flexibility Needs: Opt for Class 5 or 6 conductors for applications requiring bending, as in control or custom cables.

-

Collaborate with Manufacturers: Work with providers like Jianyun to customize conductor sizes and insulation, ensuring project compatibility.

-

Consult Professionals: Engage electricians to verify cable selection and installation, as with photovoltaic or armored cables.

These steps align with selecting effective cables like XHHW or TR-XLPE.

Conclusion

Copper conductors are essential for efficient and reliable electrical transmission, offering high conductivity, low resistance, and robust durability. Available in solid, stranded, flexible, and highly flexible configurations, they cater to diverse needs, from fixed residential wiring to dynamic industrial automation. Jianyun Cable Co., based in Luoyang, China, provides a wide range of copper conductor cables, including power, control, armored, and specialty types, ensuring high performance for global projects. By assessing application requirements, load demands, and environmental conditions, users can select the ideal copper conductor cable, building on discussions of AWG, XHHW vs. XLPE, and custom cables. Professional consultation enhances the reliability of copper conductor installations, reinforcing their pivotal role in modern electrical infrastructure.